1. Introduction

Following the exploration of foam glass, another essential material in construction and industrial applications is the waterproof backing board. Designed to withstand moisture and prevent water – related damage, waterproof backing boards play a crucial role in areas where water exposure is common, such as bathrooms, kitchens, and wet rooms. This introduction will provide a comprehensive overview of waterproof backing boards, covering their definition, composition, performance characteristics, and applications.

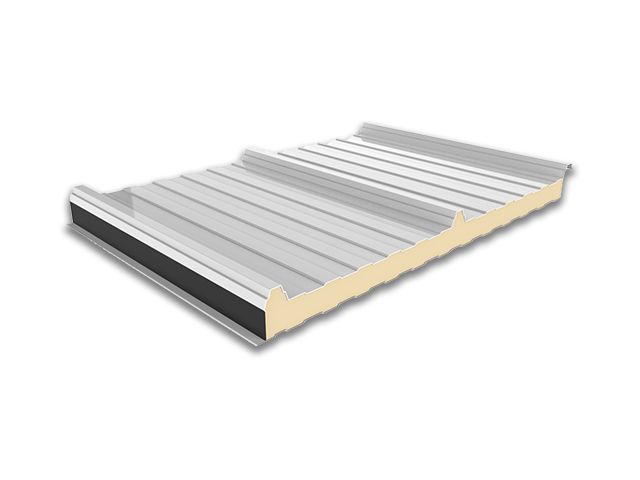

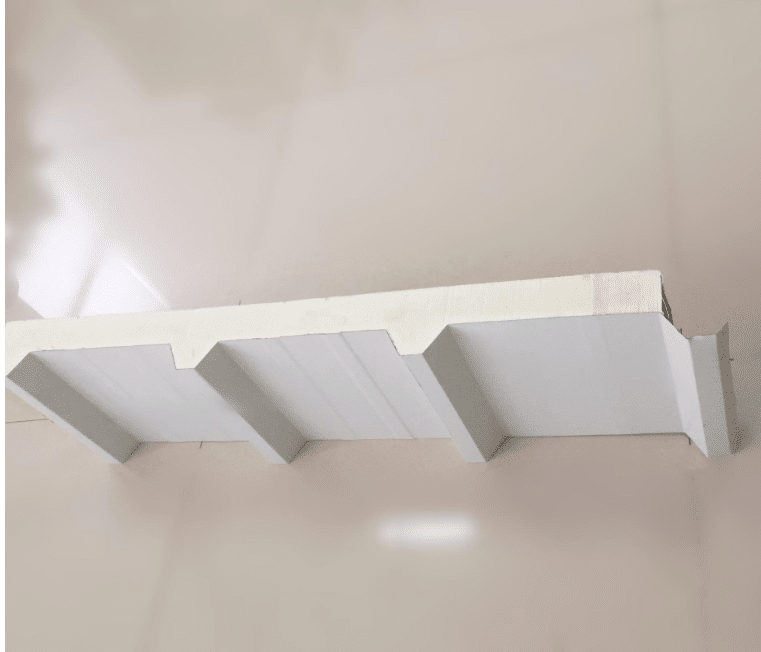

2. Definition and Composition

A waterproof backing board is a specialized panel used as a base layer in construction projects, especially in areas requiring high levels of moisture resistance. These boards are typically made from a variety of materials, each with its own unique properties. One common type is cement – based waterproof backing boards, which are composed of a mixture of Portland cement, reinforcing fibers (such as glass fibers), and aggregates. The cement provides strength and durability, while the reinforcing fibers enhance the board’s resistance to cracking, and the aggregates contribute to its overall stability.

Another type is fiber – cement waterproof backing boards, which are made by combining cement, sand, and cellulose fibers. The cellulose fibers give the board flexibility while maintaining its strength, and the cement and sand mixture ensures its waterproof and fire – resistant properties. Additionally, there are polymer – modified waterproof backing boards. These boards incorporate polymers into the material composition, improving their water resistance, adhesion, and impact resistance.

3. Performance Characteristics

3.1 Excellent Waterproofing

The primary function of a waterproof backing board is to prevent water penetration. These boards have a highly impermeable surface and structure, with a water absorption rate often less than 5%. When properly installed with appropriate sealing techniques (such as using waterproof adhesives and tapes at joints), they can effectively block water from seeping through to the underlying structures, protecting walls, floors, and building frames from moisture – induced decay, mold growth, and structural weakening.

3.2 High Mechanical Strength

Waterproof backing boards possess good mechanical strength, allowing them to support the weight of finishes such as tiles, stone, or other surface coverings. Cement – based and fiber – cement boards, for example, have high compressive and flexural strength, which can withstand the stress from foot traffic, impacts, and the weight of heavy tiles during installation and in daily use. This strength ensures the long – term stability of the installation and reduces the risk of damage or cracking over time.

3.3 Fire Resistance

Many waterproof backing boards also offer excellent fire – resistance properties. Cement – based and fiber – cement varieties, in particular, are non – combustible materials, often rated as Class A fire – resistant. This characteristic makes them suitable for use in buildings where fire safety is a concern, providing an additional layer of protection and helping to contain the spread of fire in case of an emergency.

3.4 Chemical Resistance

Waterproof backing boards are generally resistant to a wide range of chemicals commonly found in household and industrial settings. They can withstand exposure to cleaning agents, mild acids, and alkalis without significant degradation, ensuring their integrity and performance in various environments where chemical contact may occur.

3.5 Ease of Installation

Most waterproof backing boards are designed for easy installation. They can be cut to size using standard woodworking tools, and their lightweight nature (especially in the case of some polymer – modified boards) makes handling and installation more convenient. Additionally, they adhere well to different substrates, and the use of appropriate adhesives and fasteners ensures a secure and stable installation process.

4. Production Process

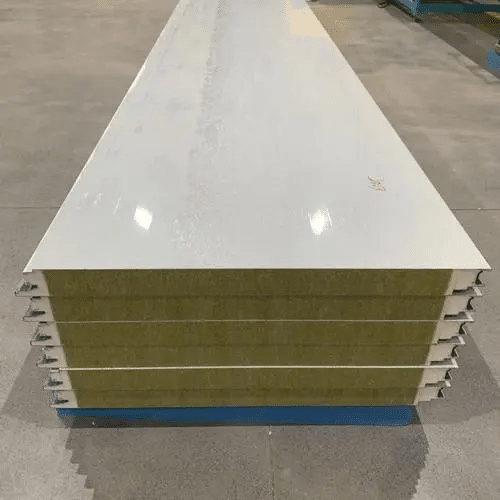

The production of cement – based waterproof backing boards typically begins with mixing Portland cement, reinforcing fibers, and aggregates in precise proportions. The mixture is then formed into boards using a pressing or extrusion process, which gives the boards their desired shape and density. After forming, the boards are cured in a controlled environment, usually under specific temperature and humidity conditions, to allow the cement to fully hydrate and gain strength.

For fiber – cement waterproof backing boards, the production process involves combining cement, sand, and cellulose fibers in a mixer. The mixture is then formed into boards, and a similar curing process follows. Polymer – modified waterproof backing boards are produced by adding polymers to the base material during the mixing stage, which modifies the properties of the final product. The boards are then shaped, cured, and may undergo additional surface treatments to enhance their performance.

5. Applications

5.1 Bathroom and Kitchen Installations

Waterproof backing boards are extensively used in bathrooms and kitchens. In bathrooms, they serve as the base layer for shower walls, bathtub surrounds, and wet room floors. By preventing water from seeping into the walls and floors, they protect the building structure from water damage, rot, and mold growth. In kitchens, they are used behind backsplashes and on countertops, providing a waterproof and durable surface that can withstand spills, splashes, and regular cleaning.

5.2 Commercial and Industrial Wet Areas

In commercial buildings such as restaurants, hotels, and hospitals, as well as in industrial facilities with wet processing areas, waterproof backing boards are crucial. They are used to line walls and floors in food preparation areas, laundry rooms, and areas where water – based cleaning and processing take place. Their ability to resist moisture, chemicals, and mechanical stress makes them a reliable choice for these demanding environments.

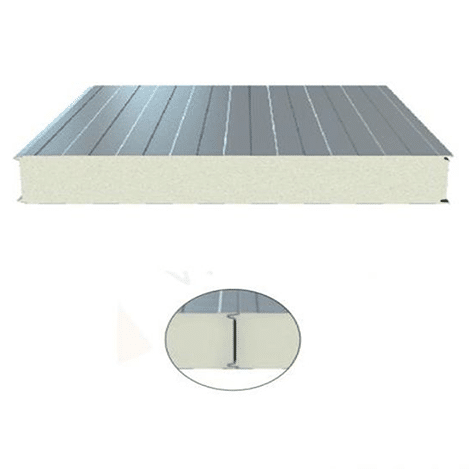

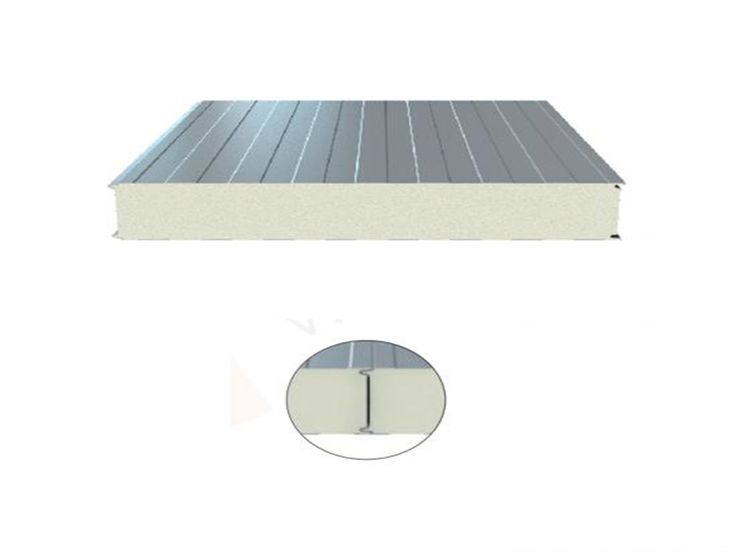

5.3 Exterior Wall Applications

Some types of waterproof backing boards can also be used in exterior wall applications, especially in regions with high humidity or frequent rainfall. They act as a moisture – barrier layer, protecting the building’s insulation and structural components from water intrusion while providing a stable surface for exterior finishes such as siding, stucco, or stone veneer.

6. Conclusion

Waterproof backing boards, with their outstanding waterproofing, mechanical strength, fire – resistance, and chemical – resistance properties, are indispensable materials in construction and industrial projects. Their wide range of applications in moisture – prone areas, combined with ease of installation, makes them a preferred choice for ensuring the durability and longevity of building structures. Whether used in residential bathrooms or large – scale commercial wet areas, waterproof backing boards continue to play a vital role in maintaining the integrity and functionality of various building components.