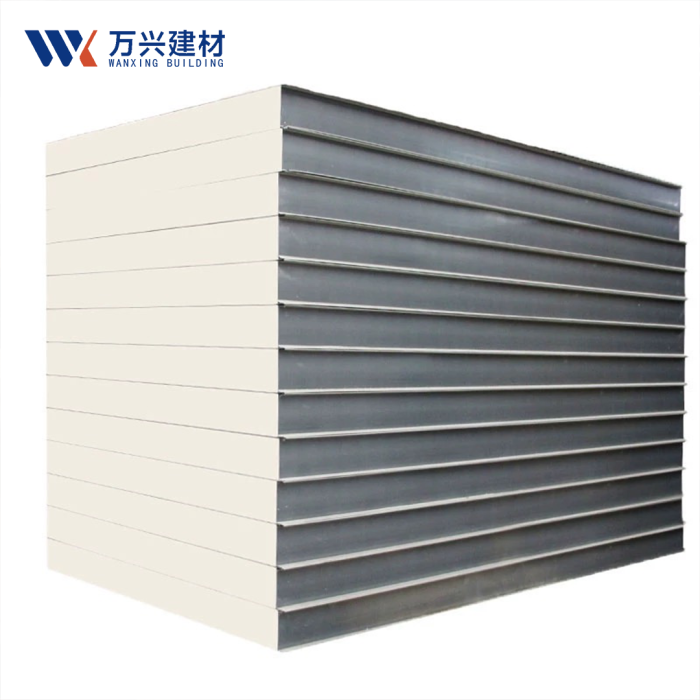

PU/PIR Sandwich Panel

- MOQ: 300m² minimum, smaller orders negotiable.

- Delivery: 15-30 days, depending on order & logistics.

- Shipping: Sea, rail, air, LCL & FCL available.

- Standards: ISO certified

- Applications: cold storage、lightweight building insulation、cold chain logistics、cleanrooms

- Customization: Available for color, size, thickness, finish.

- Payment: T/T, wire transfer, L/C, and more.

- Samples: Available (shipping at buyer’s cost); cost deductible for bulk orders.

- Customizable logo, patterns, and outer packaging

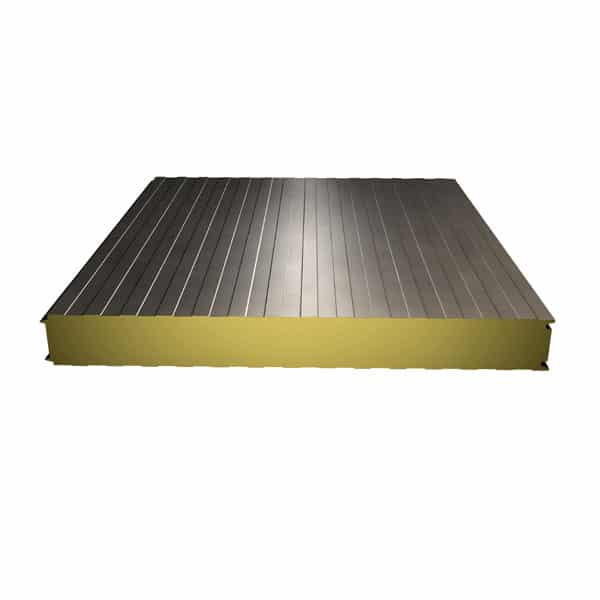

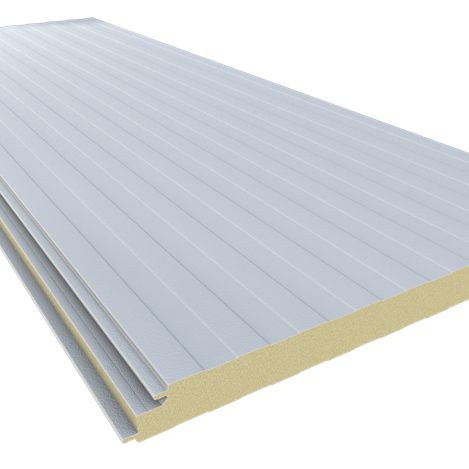

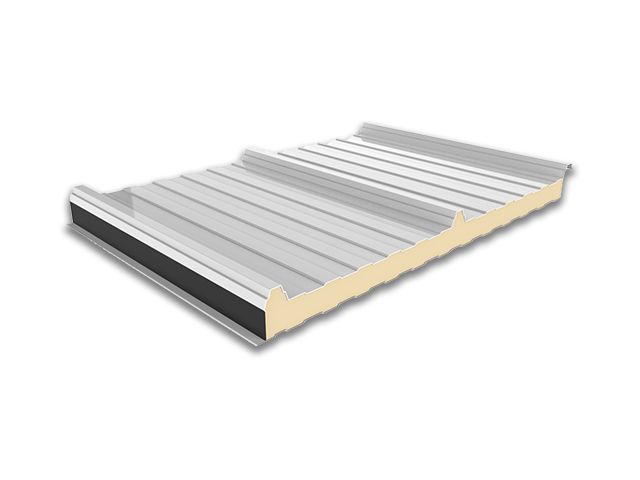

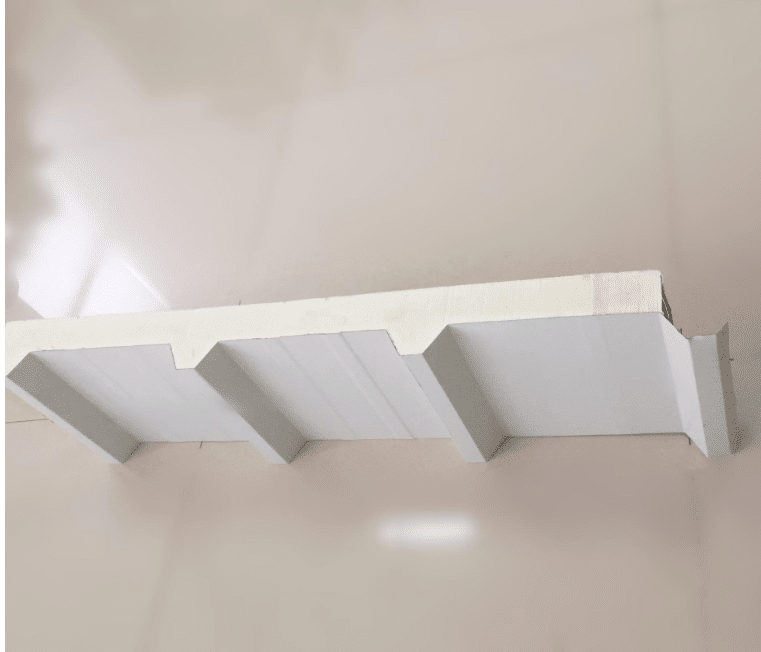

Polyurethane sandwich panels

Polyurethane Sandwich Panel (PU Sandwich Panel) is a high-performance composite material consisting of two external facings (commonly steel, aluminum, or other metal sheets) and a core made of rigid polyurethane foam. The advanced manufacturing process involves applying high-density polyurethane foam between two facings, creating a lightweight yet highly effective insulating panel that offers both structural strength and thermal efficiency.

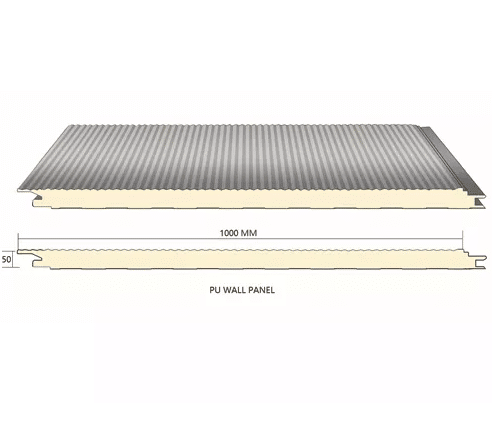

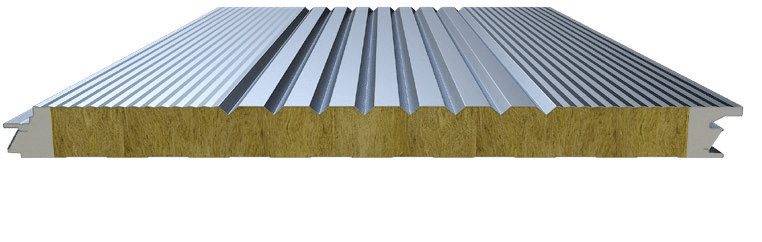

| Type | PU sandwich roof panel/polyurethane sandwich roof panel |

| Core | polyurethane |

| Density | 40-45kg/m3 |

| Surface material | color steel sheet/aluminum foil |

| Steel thickness | 0.3-0.8mm |

| Core thickness | 40/50/75/90/100/120/150/200mm |

| Length | 1000-11800mm |

| Effective Width | 1000mm |

| Fire Rating | B Class |

| Color | Any Ral color |

| Wave | three waves or four waves (36mm、45mm) |

| Advantages | Lightweight/Fireproof/Waterproof/Easy Install/Insulation |

| Surface Appearance | seamless-wave/slitwidth-wave/concave-wave/Flat/Embossed/Other |

| Usage | It is suitable for the various roofs referring to the large-size factory buildings, storage, exhibition halls, gymnasiums, freezing stores, purification workshops, etc. |

Key Features:

- Superior Thermal Insulation: Polyurethane foam has one of the lowest thermal conductivities among common insulation materials, offering excellent thermal performance with a reduced need for additional insulation. It is highly effective in maintaining internal temperatures while reducing energy consumption.

- High Strength-to-Weight Ratio: The sandwich structure, which combines a lightweight foam core with strong facings, provides excellent mechanical strength without the bulk of traditional materials. This makes it easy to handle and reduces overall construction costs.

- Fire Resistance: While not inherently fireproof, the fire resistance of polyurethane panels can be enhanced with the use of fire-retardant additives. Many PU sandwich panels meet or exceed fire safety standards, making them suitable for various applications that require fire protection.

- Acoustic Insulation: Due to its dense and uniform foam core, polyurethane sandwich panels also provide excellent sound insulation, helping to reduce noise transmission between spaces, which is especially beneficial in industrial and residential buildings.

- Moisture Resistance: The closed-cell structure of the polyurethane foam core makes the panel highly resistant to water absorption, preventing moisture-related issues like mold growth and deterioration.

Applications:

Polyurethane sandwich panels are used across various sectors due to their versatile properties. Their main applications include:

- Building Construction: As wall panels, roofing systems, and cladding for both residential and commercial buildings, providing thermal efficiency and durability.

- Cold Storage and Refrigeration: Due to their superior insulation properties, PU sandwich panels are widely used in cold storage warehouses, refrigerated transport, and food processing facilities.

- Industrial Facilities: They are used in the construction of factories, clean rooms, and warehouses where thermal insulation, structural integrity, and fire resistance are critical.

- Transport: Used in refrigerated vehicles, containers, and mobile cold storage solutions due to their lightweight and insulation capabilities.

With the ability to reduce energy costs, provide long-lasting insulation, and support sustainable building practices, polyurethane sandwich panels are an essential material for modern construction and industrial applications.

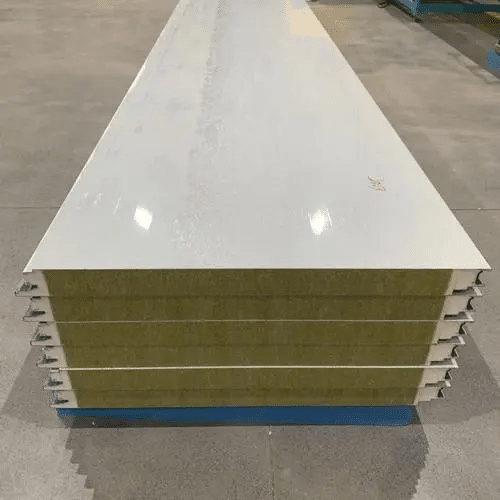

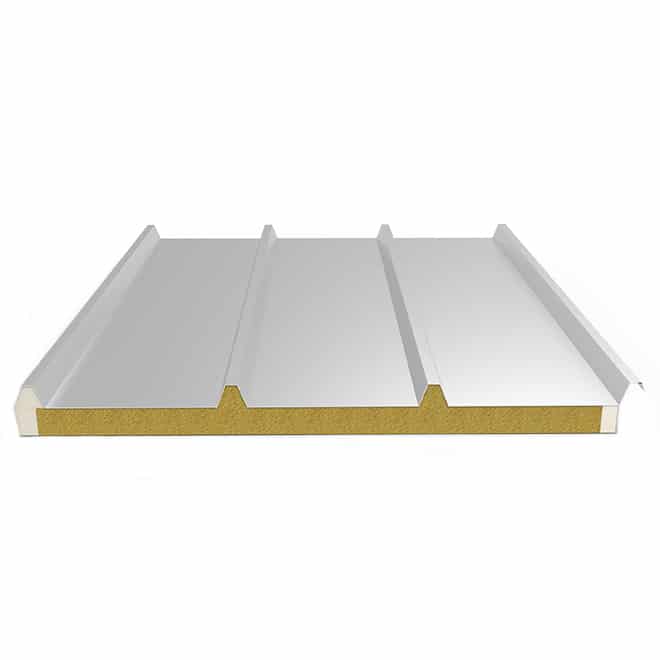

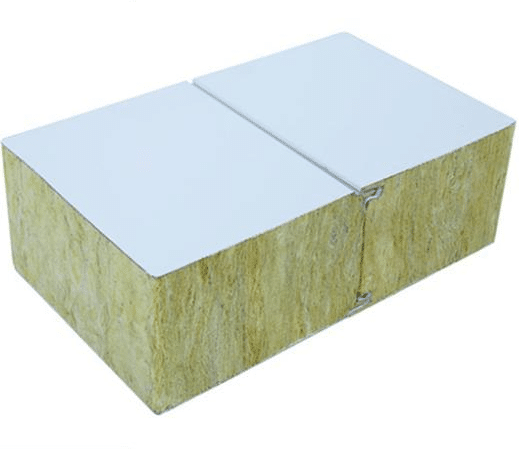

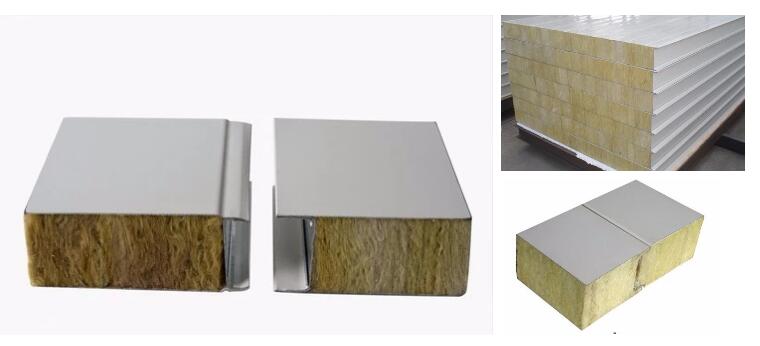

PIR Sandwich Panels

PIR Sandwich Panels (Polyisocyanurate Sandwich Panels) are advanced composite building materials consisting of a polyisocyanurate (PIR) foam core sandwiched between two layers of metal or non-metallic facings. Renowned for their outstanding thermal insulation, excellent fire resistance, and high strength-to-weight ratio, PIR panels are widely utilized in applications demanding energy efficiency, fire safety, and structural stability. Compared to traditional insulation materials, PIR sandwich panels offer superior fire performance and reduced smoke emission while maintaining a low thermal conductivity, making them an ideal choice for modern construction.

Key Features

- Outstanding Thermal Insulation: Low thermal conductivity (0.022 – 0.026 W/m·K), minimizing heat transfer and enhancing energy efficiency.

- Excellent Fire Resistance: Achieves B1 or higher fire rating with minimal smoke and toxic gas emissions during combustion.

- Lightweight & High Strength: Lightweight design with robust structural integrity, facilitating easy installation and transport.

- High Durability: Resistant to water, moisture, and corrosion, suitable for diverse environments.

- Eco-Friendly & Energy-Saving: Environmentally conscious production process with exceptional insulation properties, reducing building energy consumption.

Applications

PIR sandwich panels are extensively used in cold storage facilities, industrial warehouses, cleanrooms, commercial building facades and roofing, as well as partition and ceiling systems requiring stringent fire safety standards.

Technical Specifications

- Core Material: Polyisocyanurate (PIR) foam

- Thickness: 20mm – 200mm

- Density: 40 kg/m³

- Thermal Conductivity: 0.022 – 0.026 W/m·K

- Facing Material: Pre-painted steel, stainless steel, aluminum, etc.

With their superior performance and versatility, PIR sandwich panels are a preferred solution for energy-efficient construction and industrial applications.

Differences Between PIR and PU

PIR (Polyisocyanurate) and PU (Polyurethane) are two common foam materials widely used as core materials in sandwich panels. While they share some similarities in chemical composition and properties, there are notable differences. Below is a detailed comparison:

1. Chemical Composition

- PU (Polyurethane): Formed by the reaction of polyols and isocyanates, it is a common foam plastic with urethane bonds in its molecular structure.

- PIR (Polyisocyanurate): Also produced from polyols and isocyanates, but with adjusted formulations and catalysts, it forms more isocyanurate ring structures, enhancing its chemical stability.

2. Fire Performance

- PU: Typically has a fire rating of B2 or B3 (depending on the formulation), producing more smoke and toxic gases when burned, with weaker fire resistance.

- PIR: Offers superior fire performance, often achieving a B1 or higher rating. PIR forms a carbonized layer at high temperatures, slowing combustion and significantly reducing smoke and toxic gas emissions compared to PU.

3. Thermal Insulation

- PU: Thermal conductivity typically ranges from 0.024 to 0.030 W/m·K, providing good insulation performance.

- PIR: Slightly lower thermal conductivity (0.022 – 0.026 W/m·K), offering marginally better insulation, especially with more stable performance over time.

4. High-Temperature Resistance

- PU: Limited temperature resistance (generally around 100°C), prone to decomposition at higher temperatures.

- PIR: Better heat resistance (up to 150°C or higher), with greater thermal stability, making it suitable for high-temperature environments.

5. Production Cost

- PU: Simpler production process and lower cost, ideal for applications with less stringent fire requirements.

- PIR: More complex formulation and production process, leading to higher costs, but with significantly improved performance.

6. Applications

- PU: Commonly used in standard cold storage, lightweight building insulation, and general industrial purposes.

- PIR: Preferred for applications requiring higher fire resistance and insulation, such as cold chain logistics, cleanrooms, industrial plants, and buildings with strict fire safety standards.

Summary

In essence, PIR is an enhanced version of PU, optimized for better fire resistance, thermal insulation, and high-temperature stability through its chemical structure. The choice between PIR and PU depends on specific needs: PU is a cost-effective option for applications with lower fire safety demands, while PIR is better suited for scenarios requiring superior safety and performance.

Detailed Shipping Options Introduction

At Wanxing, we offer flexible shipping options tailored to your procurement needs. Strategically located near Qingdao, a major port city renowned for its robust shipping infrastructure, we provide two convenient choices to suit your project demands:

- Our Full Shipping Service: Let us handle the logistics from start to finish. We’ll manage the entire process—from packing your EIFS panels at our facility near Qingdao to delivering them directly to your construction site. Leveraging Qingdao Port’s efficient sea and air transport networks, we can ship to key markets like Europe (e.g., Rotterdam in 20-30 days via sea), North America (e.g., Los Angeles in 25-35 days), or other global destinations. Our team coordinates with trusted freight forwarders to ensure timely delivery, keeping your project on schedule. This turnkey solution is ideal if you prefer a hands-off approach with guaranteed reliability.

- Self-Pickup with Ex-Factory Pricing: For maximum cost control, opt to collect your panels directly from our facility near Qingdao or at Qingdao Port. With ex-factory pricing, you avoid additional shipping markups and can arrange your own logistics—whether sea freight for bulk orders (e.g., containers of 500+ panels) or air freight for urgent needs. This option lets you optimize shipping costs and timelines based on your preferred carriers and routes, offering flexibility for tight budgets or specific delivery windows.

To support either choice, we provide all necessary documentation, including invoices, packing lists, and customs forms, ensuring compliance with international regulations. Need help with logistics? We can recommend experienced freight forwarders familiar with Qingdao’s export processes to streamline customs clearance and delivery to your site. Our goal is to make procurement seamless and cost-effective, whether you’re building in Europe, North America, or beyond. Want a shipping plan that perfectly fits your project’s budget and timeline? Contact us today to customize a solution from Qingdao, tailored to your needs.