PU/PIR Roof Sandwich Panels – High-Performance Thermal & Fireproof Roofing Solution

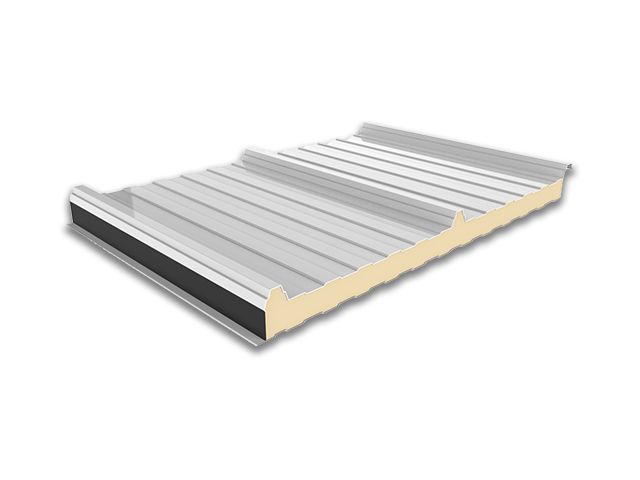

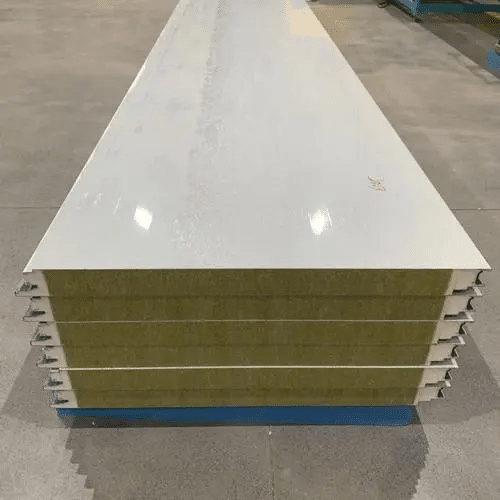

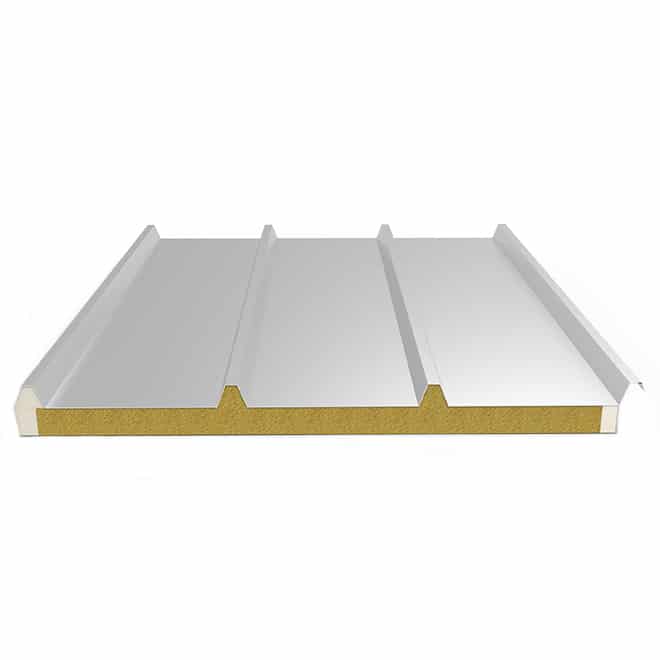

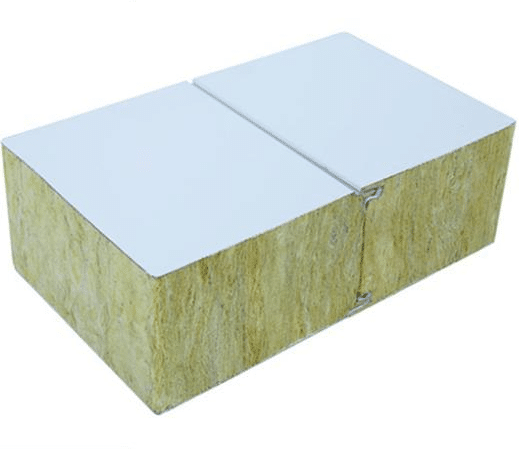

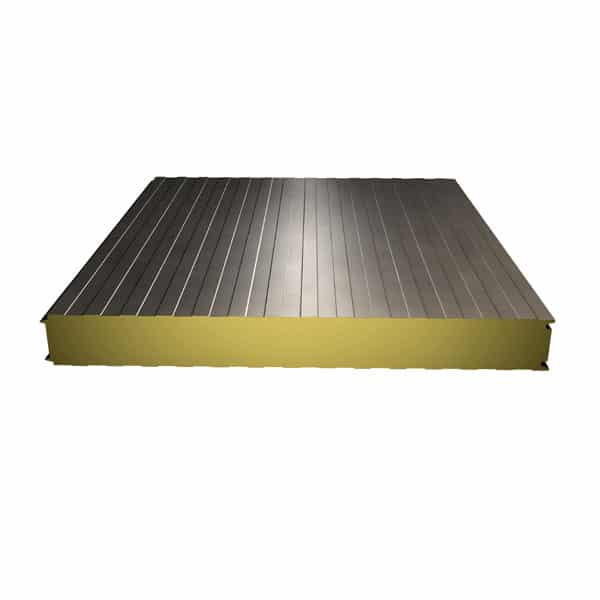

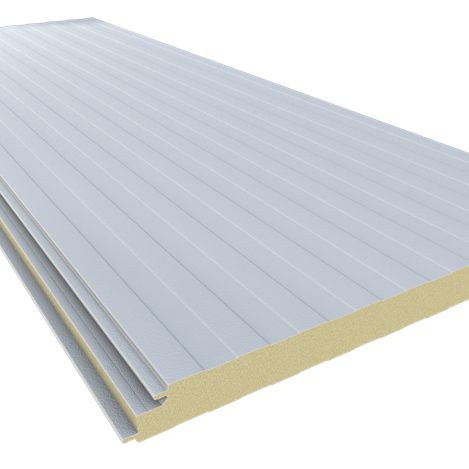

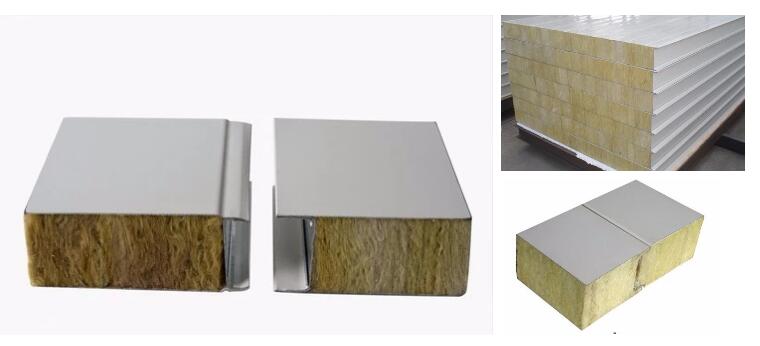

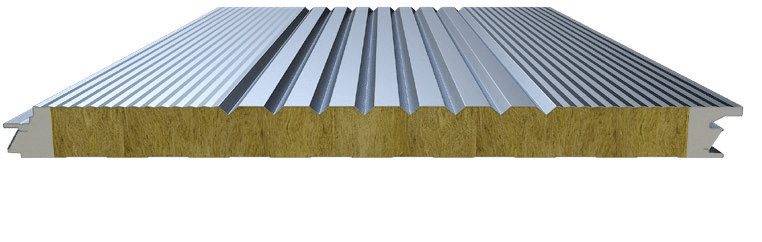

PU/PIR roof sandwich panels are advanced thermal insulation roofing materials featuring a polyurethane (PU) or polyisocyanurate (PIR) rigid foam core, bonded between high-strength galvanized steel, aluminum, or pre-painted steel sheets. These panels provide exceptional thermal resistance, mechanical strength, and fire safety, making them ideal for industrial, commercial, and cold storage roofing applications.

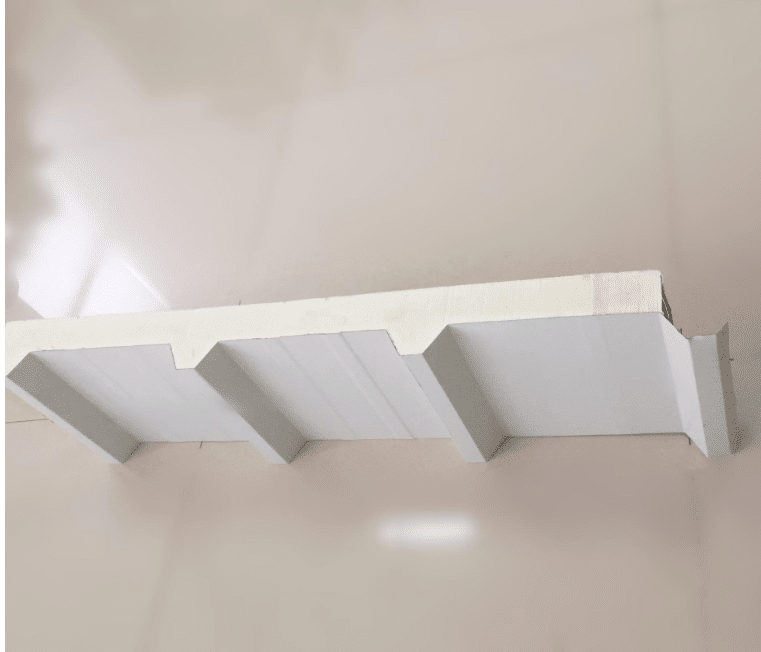

PIR panels offer B1 fire classification, ensuring improved fire-retardant performance compared to standard PU panels. The precision tongue-and-groove or overlapping joint designs enhance structural stability and weather resistance, minimizing thermal bridging and water infiltration.

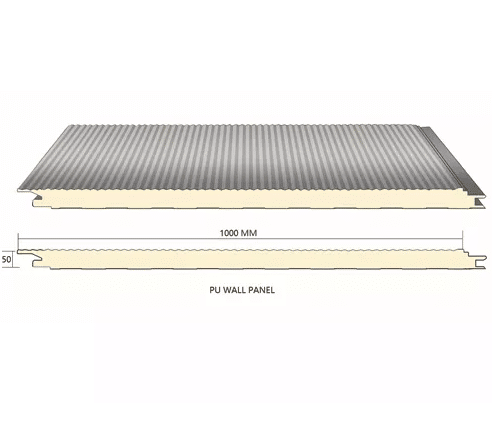

| Structure | Three layers: ① Upper layer: steel sheet ② Inner layer: PU sandwich ③ Bottom layer: steel sheet |

|---|---|

| Steel Thickness | 0.4~0.7mm |

| Panel Thickness | 50–200mm |

| Length | 1–11.8m |

| Effective Width | 1000mm |

| Core Material | Polyurethane (PU) foam |

| Density | 40–45 kg/m³ |

| Color | RAL Color |

| Parts | Steel line for easy connection, protective film covering |

| Lifetime | About 30 years |

| Characteristics | Lightweight, heat insulation, fireproof, waterproof, environmentally friendly |

| Usage | Large-scale factory buildings, warehouses, exhibition halls, gymnasiums, etc. |

| Packing | Packed in shipping containers or as per customer requirements |

Detailed Shipping Options Introduction

At Wanxing, we offer flexible shipping options tailored to your procurement needs. Strategically located near Qingdao, a major port city renowned for its robust shipping infrastructure, we provide two convenient choices to suit your project demands:

- Our Full Shipping Service: Let us handle the logistics from start to finish. We’ll manage the entire process—from packing your EIFS panels at our facility near Qingdao to delivering them directly to your construction site. Leveraging Qingdao Port’s efficient sea and air transport networks, we can ship to key markets like Europe (e.g., Rotterdam in 20-30 days via sea), North America (e.g., Los Angeles in 25-35 days), or other global destinations. Our team coordinates with trusted freight forwarders to ensure timely delivery, keeping your project on schedule. This turnkey solution is ideal if you prefer a hands-off approach with guaranteed reliability.

- Self-Pickup with Ex-Factory Pricing: For maximum cost control, opt to collect your panels directly from our facility near Qingdao or at Qingdao Port. With ex-factory pricing, you avoid additional shipping markups and can arrange your own logistics—whether sea freight for bulk orders (e.g., containers of 500+ panels) or air freight for urgent needs. This option lets you optimize shipping costs and timelines based on your preferred carriers and routes, offering flexibility for tight budgets or specific delivery windows.

To support either choice, we provide all necessary documentation, including invoices, packing lists, and customs forms, ensuring compliance with international regulations. Need help with logistics? We can recommend experienced freight forwarders familiar with Qingdao’s export processes to streamline customs clearance and delivery to your site. Our goal is to make procurement seamless and cost-effective, whether you’re building in Europe, North America, or beyond. Want a shipping plan that perfectly fits your project’s budget and timeline? Contact us today to customize a solution from Qingdao, tailored to your needs.