Phenolic Sandwich Panels

- MOQ: 300m² minimum, smaller orders negotiable.

- Delivery: 15-30 days, depending on order & logistics.

- Shipping: Sea, rail, air, LCL & FCL available.

- Standards: ISO certified

- Customization: Available for color, size, thickness, finish.

- Payment: T/T, wire transfer, L/C, and more.

- Samples: Available (shipping at buyer’s cost); cost deductible for bulk orders.

- Customizable logo, patterns, and outer packaging

Phenolic Sandwich Panels

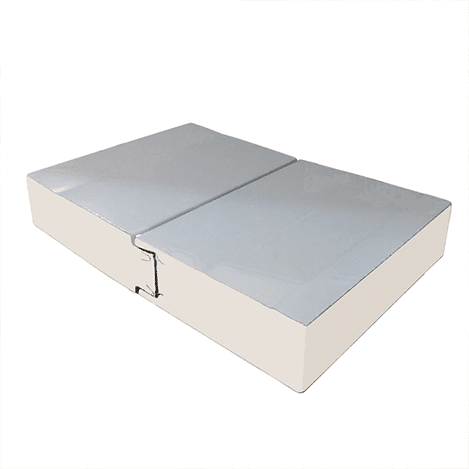

1. Product Overview

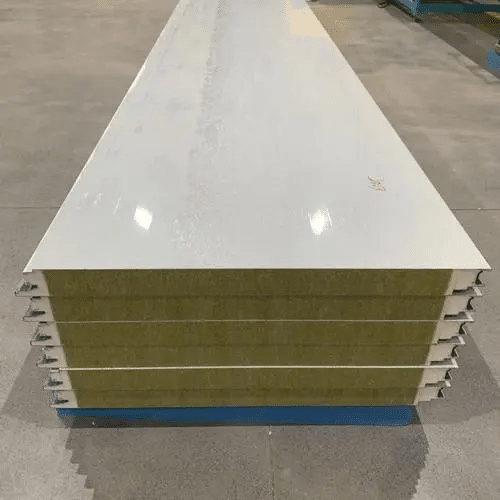

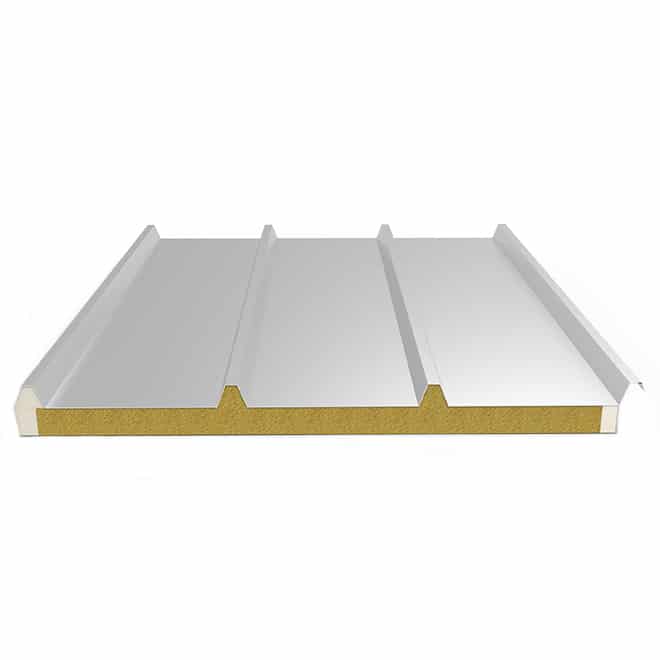

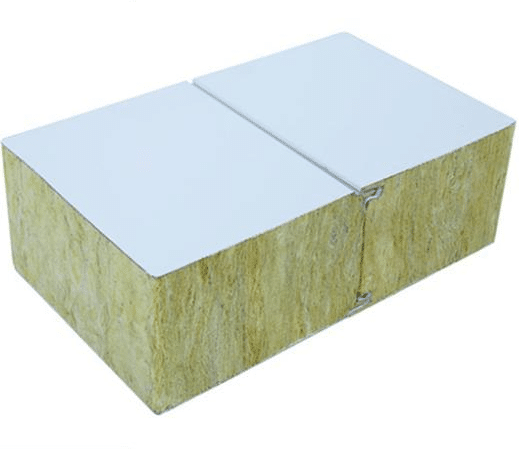

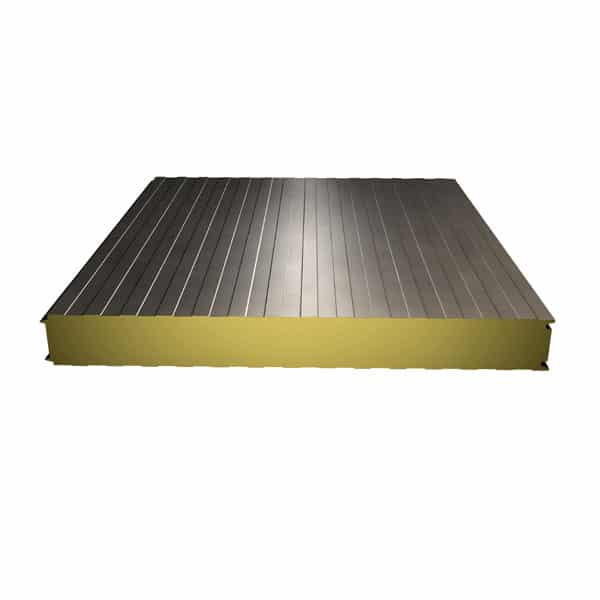

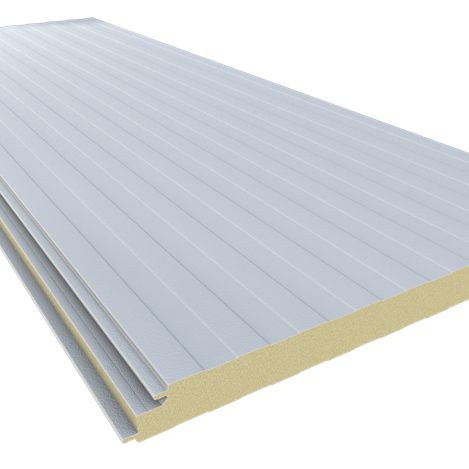

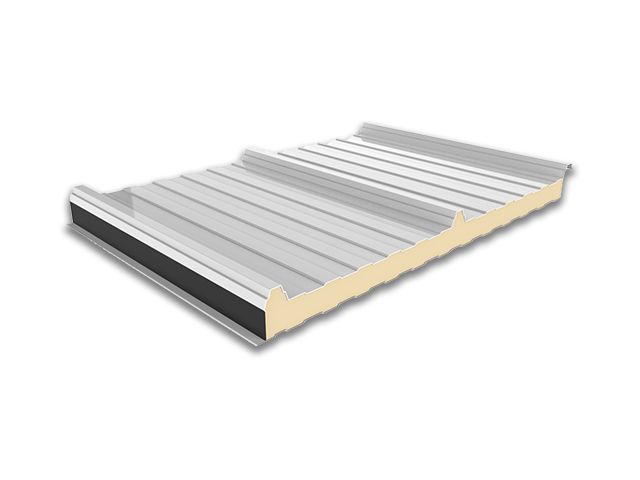

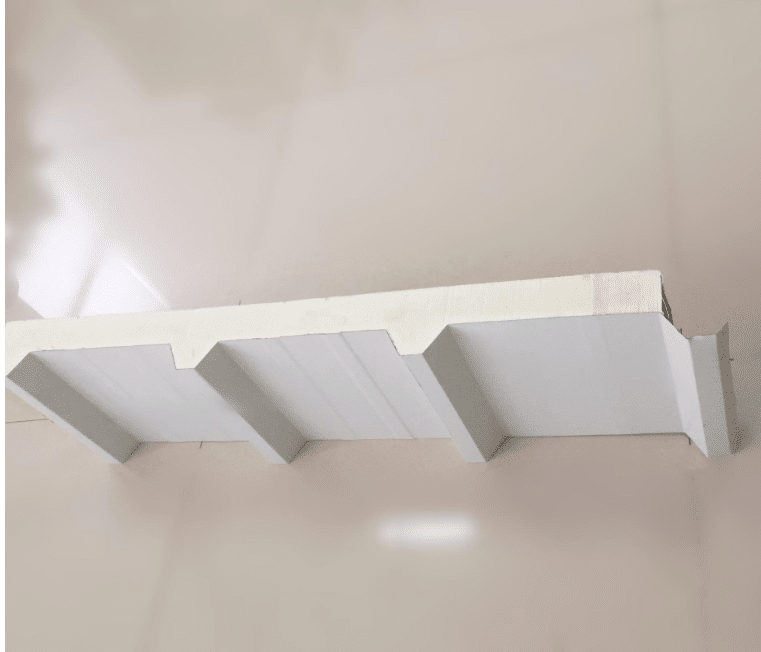

Phenolic Sandwich Panels are high-performance composite panels featuring a phenolic foam core sandwiched between two layers of metal or non-metallic facings. Phenolic foam is known for its exceptional fire resistance, low smoke emission, and excellent thermal insulation properties. These panels are widely used in applications requiring stringent fire safety standards, superior thermal efficiency, and lightweight construction.

2. Key Features

- Excellent Fire Resistance

- Phenolic foam has a high fire rating (Class A), producing minimal smoke and toxic gases in case of fire.

- Superior Thermal Insulation

- Low thermal conductivity (0.020 – 0.030 W/m·K), reducing heat transfer and improving energy efficiency.

- Lightweight & High Strength

- Compared to traditional insulation materials, phenolic panels are lightweight yet structurally strong.

- Water & Moisture Resistance

- Closed-cell phenolic foam prevents water absorption, maintaining its insulating properties over time.

- Low Smoke & Toxic Emissions

- Suitable for environments where smoke control and safety are critical.

- Chemical & Corrosion Resistance

- Resistant to most chemicals, acids, and alkalis, ensuring durability in harsh environments.

3. Applications

- HVAC ducting systems

- Cleanrooms and medical facilities

- Fire-rated walls and partitions

- Cold storage and refrigeration units

- Industrial and commercial buildings

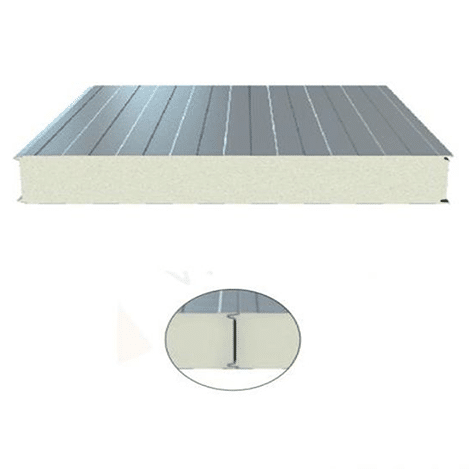

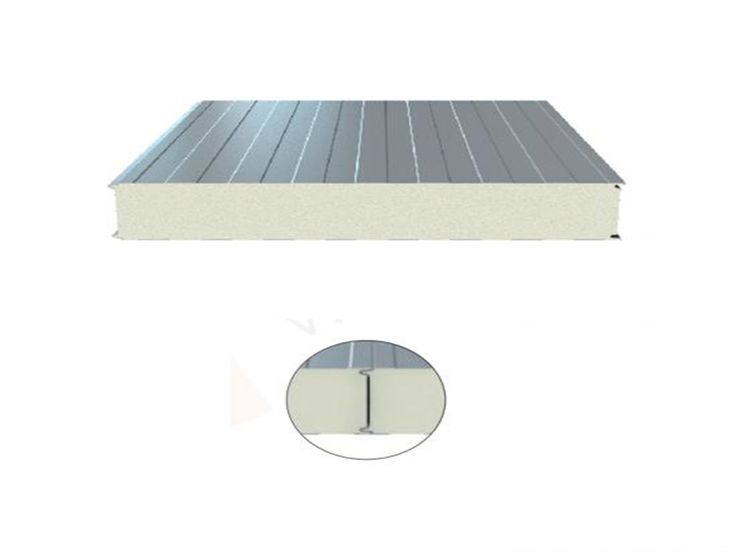

4. Technical Specifications

- Core Material: Phenolic foam

- Panel Thickness: 20mm – 200mm

- Thermal Conductivity: 0.020 – 0.030 W/m·K

- Fire Resistance: Class A (non-combustible, low smoke emission)

- Density: 40 – 100 kg/m³

- Water Absorption Rate: ≤ 1.5%

- Facing Material: Pre-painted galvanized steel (PPGI), stainless steel, aluminum, fiber cement board

5. Advantages

- Highest fire safety rating with low smoke emission

- Excellent thermal efficiency for energy-saving applications

- Lightweight yet highly durable construction

- Resistant to water, chemicals, and corrosion

- Ideal for environments with strict fire and smoke regulations

Detailed Shipping Options Introduction

At Wanxing, we offer flexible shipping options tailored to your procurement needs. Strategically located near Qingdao, a major port city renowned for its robust shipping infrastructure, we provide two convenient choices to suit your project demands:

- Our Full Shipping Service: Let us handle the logistics from start to finish. We’ll manage the entire process—from packing your EIFS panels at our facility near Qingdao to delivering them directly to your construction site. Leveraging Qingdao Port’s efficient sea and air transport networks, we can ship to key markets like Europe (e.g., Rotterdam in 20-30 days via sea), North America (e.g., Los Angeles in 25-35 days), or other global destinations. Our team coordinates with trusted freight forwarders to ensure timely delivery, keeping your project on schedule. This turnkey solution is ideal if you prefer a hands-off approach with guaranteed reliability.

- Self-Pickup with Ex-Factory Pricing: For maximum cost control, opt to collect your panels directly from our facility near Qingdao or at Qingdao Port. With ex-factory pricing, you avoid additional shipping markups and can arrange your own logistics—whether sea freight for bulk orders (e.g., containers of 500+ panels) or air freight for urgent needs. This option lets you optimize shipping costs and timelines based on your preferred carriers and routes, offering flexibility for tight budgets or specific delivery windows.

To support either choice, we provide all necessary documentation, including invoices, packing lists, and customs forms, ensuring compliance with international regulations. Need help with logistics? We can recommend experienced freight forwarders familiar with Qingdao’s export processes to streamline customs clearance and delivery to your site. Our goal is to make procurement seamless and cost-effective, whether you’re building in Europe, North America, or beyond. Want a shipping plan that perfectly fits your project’s budget and timeline? Contact us today to customize a solution from Qingdao, tailored to your needs.