Insulation and Decoration Integrated Panel

Product Information

- Price: From $15/m² (final price based on order & shipping).

- MOQ: 300m² minimum, smaller orders negotiable.

- Delivery: 15-30 days, depending on order & logistics.

- Shipping: Sea, rail, air, LCL & FCL available.

- Standards: ISO certified

- Applications: Residential, commercial, industrial, government.

- Customization: Available for color, size, thickness, finish.

- Payment: T/T, wire transfer, L/C, and more.

- Samples: Available (shipping at buyer’s cost); cost deductible for bulk orders.

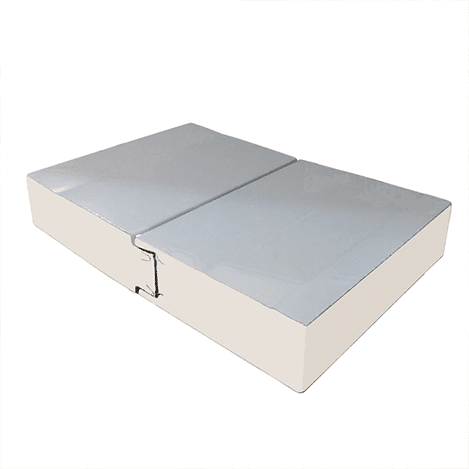

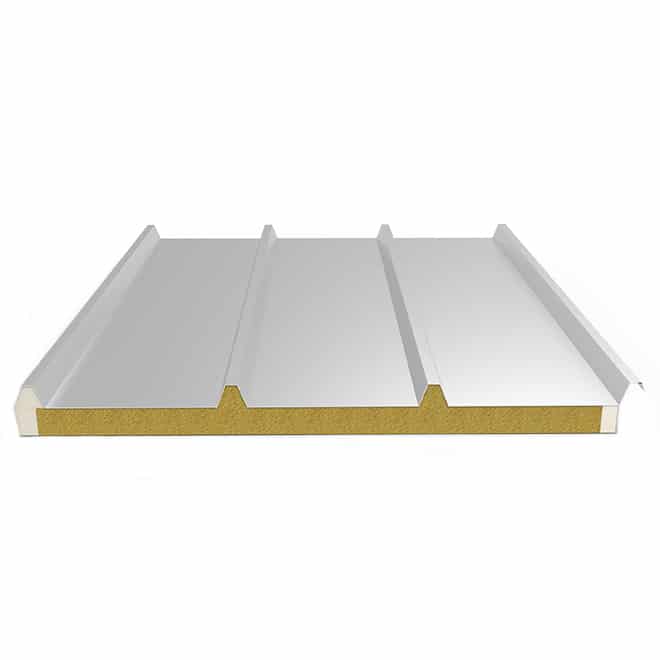

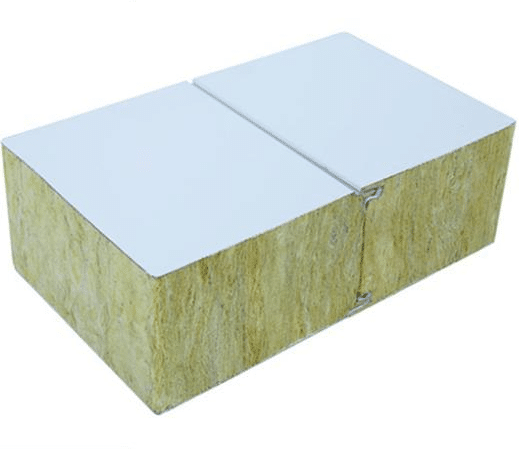

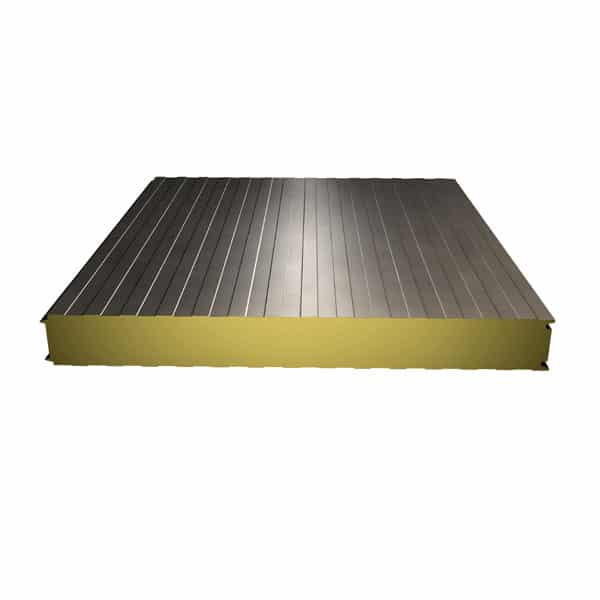

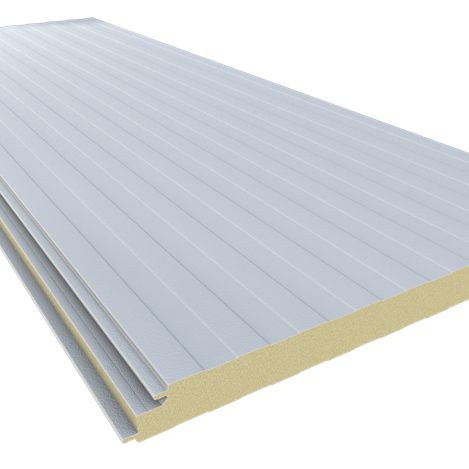

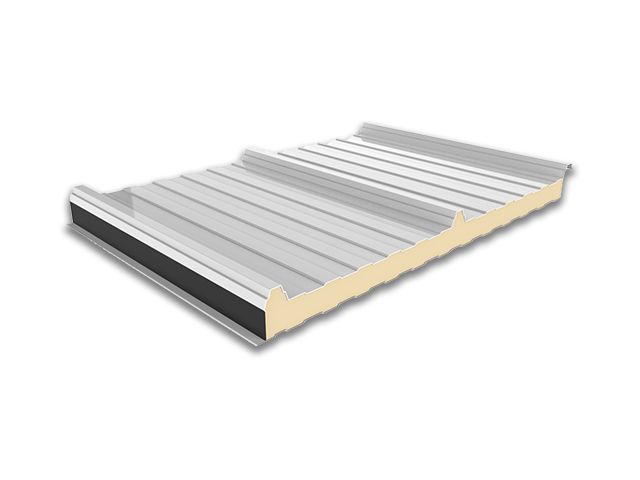

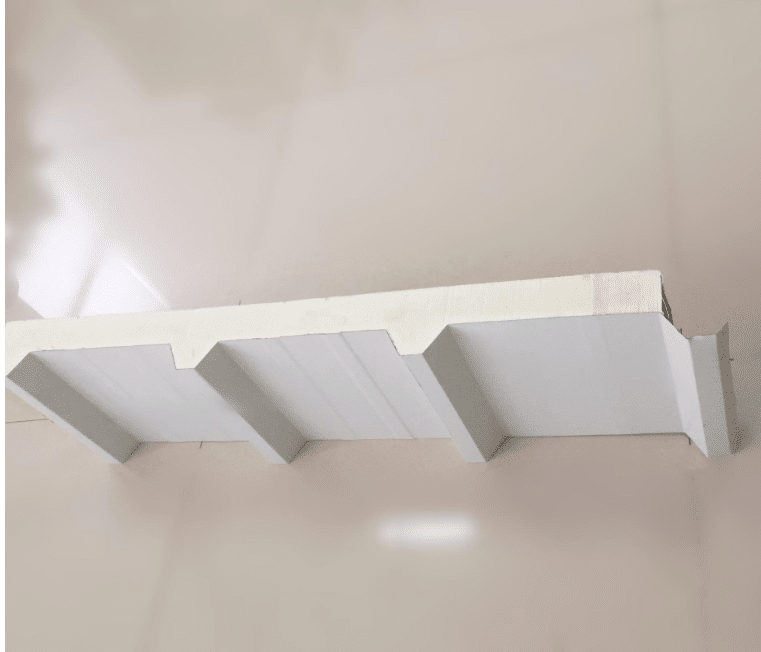

The Insulation and Decoration Integrated Panel (IDIP) is an advanced prefabricated exterior wall system that integrates thermal insulation, structural reinforcement, and architectural aesthetics into a single panel. This innovative building solution enhances energy efficiency, optimizes façade durability, and accelerates construction processes compared to traditional insulation and finishing methods.

Structural Composition

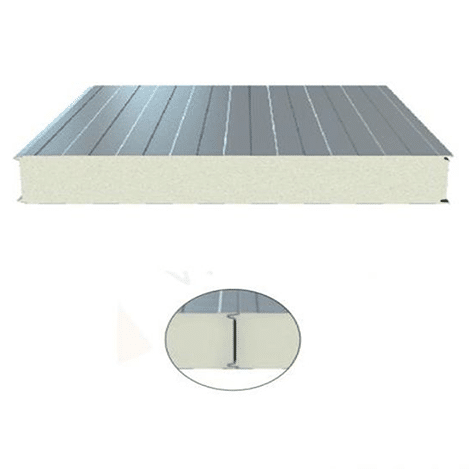

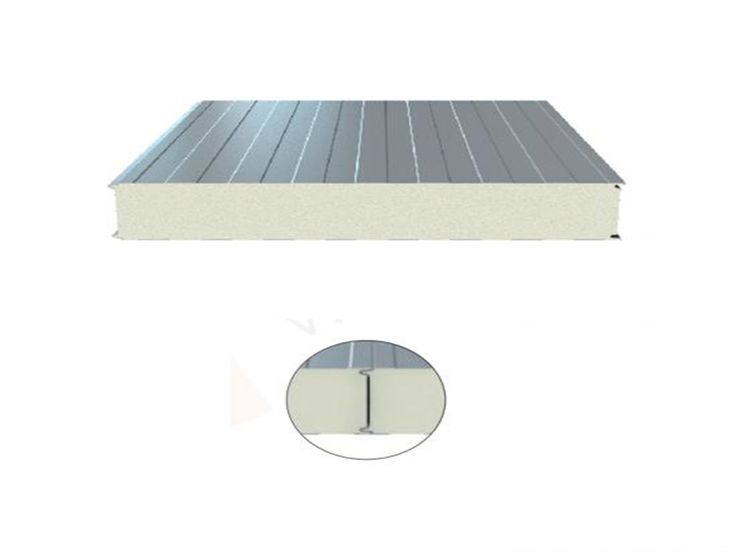

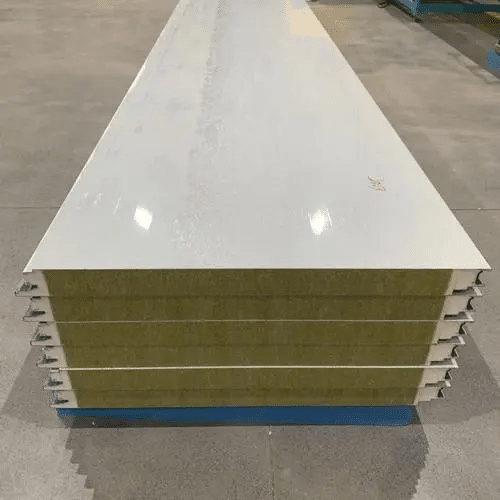

The IDIP consists of a multi-layered system engineered for superior performance:

-

Insulation Core – Provides high thermal resistance (R-value) and energy efficiency. Common insulation materials include:

- EPS (Expanded Polystyrene) – Lightweight, cost-effective, and suitable for general applications.

- XPS (Extruded Polystyrene) – Offers higher compressive strength and moisture resistance.

- PU (Polyurethane Foam) – Provides superior insulation with a lower thermal conductivity.

- Rock Wool (Mineral Wool) – Non-combustible and excellent for fire-rated applications.

-

Decorative Surface Layer – Designed to withstand environmental exposure while offering aesthetic versatility. Surface finishes include:

- Metal Cladding (Aluminum, Stainless Steel, etc.) – Lightweight and corrosion-resistant.

- Stone Veneer or Textured Coating – Mimics natural stone for premium architectural designs.

- Ceramic Tile or Porcelain Finish – Highly durable and impact-resistant.

- Silicone Acrylic Coatings – Flexible, weather-resistant, and customizable in color and texture.

-

Reinforcement and Backing Layer – Enhances mechanical strength and panel stability. This layer is often made of:

- Fiberglass-reinforced Cement Board – Adds impact resistance and structural integrity.

- Magnesium Oxide Board (MGO) – Provides fire resistance and mold resistance.

- Galvanized Steel Backing – Used in high-strength applications to improve rigidity.

Key Performance Benefits

- Superior Thermal Efficiency: Reduces heat transfer and enhances building envelope performance, leading to lower HVAC energy consumption.

- Integrated Fire Resistance: Rock wool and MGO-based panels meet Class A fire safety standards, ensuring compliance with global fire codes.

- High Structural Durability: Resistant to cracking, delamination, and mechanical impact, ensuring long-term performance.

- Weather and UV Resistance: The outer finish is engineered to withstand extreme temperatures, moisture penetration, and prolonged UV exposure.

- Prefabrication and Rapid Installation: Factory-processed panels minimize on-site labor, reduce construction waste, and expedite project timelines.

- Lightweight and Seismic-Resistant: Suitable for high-rise buildings and retrofitting projects, reducing the overall structural load.

- Sustainable and Eco-Friendly: Many IDIP systems incorporate recyclable materials, contributing to green building certifications such as LEED and BREEAM.

Applications

The Insulation and Decoration Integrated Panel is widely used in:

- Commercial and Office Buildings – Achieves high-end architectural aesthetics with thermal efficiency.

- Residential Housing and High-Rise Apartments – Enhances insulation and structural safety.

- Industrial Facilities and Warehouses – Provides energy-saving solutions with durable exteriors.

- Old Building Renovation Projects – Upgrades existing structures with modernized, energy-efficient façades.

By integrating insulation and decoration into a single prefabricated system, IDIP provides an efficient, high-performance, and aesthetically adaptable solution for contemporary architecture.

| Item | Specification/Description |

|---|---|

| Finish Layer | Stone, ceramic panels, sand-textured coating, water-based coating, stone-like paint, fluorocarbon paint, UV coating, etc. (customizable per client requirements) |

| Insulation Layer | PU (Polyurethane)/XPS (Extruded Polystyrene)/EPS (Expanded Polystyrene)/RW (Rock Wool)/Graphite board/Class A insulation board |

| Insulation Thickness | <15cm |

| Installation Method | Adhesive + Mechanical Anchoring |

| Weight | 16-20 KG/m² |

| Maximum Size | 600x800mm (custom sizes available) |

| Warranty | Over 25 years |

| Advantages | Energy-saving, easy installation, natural stone-like appearance, avoids defects of natural stone, simple construction, safe operation, cost-effective |

| Applications | External wall insulation and decoration for multi-story/high-rise residential buildings, villas, office buildings, and renovation of existing walls |

| Tensile Strength | 0.10-0.15 MPa (depending on insulation material strength) |

| Fire Rating | Organic insulation boards: Class B1; Rock wool and inorganic insulation boards: Class A |

| Thermal Conductivity | Complies with relevant insulation material standards |

Application Effect

Detailed Shipping Options Introduction

At Wanxing, we offer flexible shipping options tailored to your procurement needs. Strategically located near Qingdao, a major port city renowned for its robust shipping infrastructure, we provide two convenient choices to suit your project demands:

- Our Full Shipping Service: Let us handle the logistics from start to finish. We’ll manage the entire process—from packing your EIFS panels at our facility near Qingdao to delivering them directly to your construction site. Leveraging Qingdao Port’s efficient sea and air transport networks, we can ship to key markets like Europe (e.g., Rotterdam in 20-30 days via sea), North America (e.g., Los Angeles in 25-35 days), or other global destinations. Our team coordinates with trusted freight forwarders to ensure timely delivery, keeping your project on schedule. This turnkey solution is ideal if you prefer a hands-off approach with guaranteed reliability.

- Self-Pickup with Ex-Factory Pricing: For maximum cost control, opt to collect your panels directly from our facility near Qingdao or at Qingdao Port. With ex-factory pricing, you avoid additional shipping markups and can arrange your own logistics—whether sea freight for bulk orders (e.g., containers of 500+ panels) or air freight for urgent needs. This option lets you optimize shipping costs and timelines based on your preferred carriers and routes, offering flexibility for tight budgets or specific delivery windows.

To support either choice, we provide all necessary documentation, including invoices, packing lists, and customs forms, ensuring compliance with international regulations. Need help with logistics? We can recommend experienced freight forwarders familiar with Qingdao’s export processes to streamline customs clearance and delivery to your site. Our goal is to make procurement seamless and cost-effective, whether you’re building in Europe, North America, or beyond. Want a shipping plan that perfectly fits your project’s budget and timeline? Contact us today to customize a solution from Qingdao, tailored to your needs.