Foam glass

Foam glass, also known as cellular glass, is a porous inorganic non – metallic material with unique properties. It has emerged as a preferred choice in various industries due to its outstanding performance in insulation, fire resistance, and durability.

2. Production Process

3. Performance Characteristics

3.1 Thermal Insulation

3.2 Fire Resistance

3.3 Moisture Resistance

3.4 Chemical Stability

3.5 Mechanical Strength

3.6 Sound Absorption

4. Applications

4.1 Building Industry

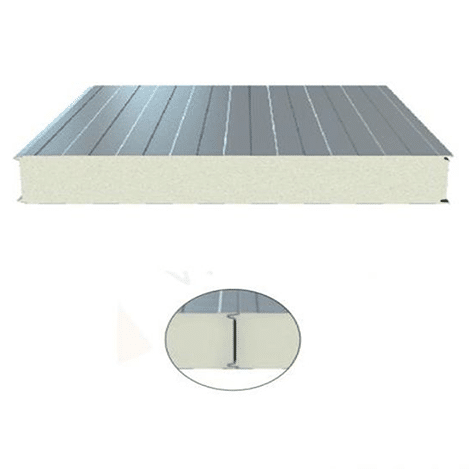

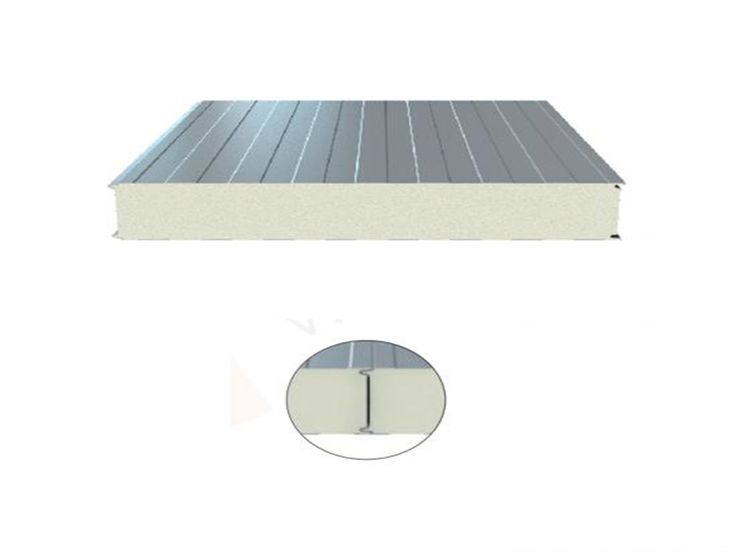

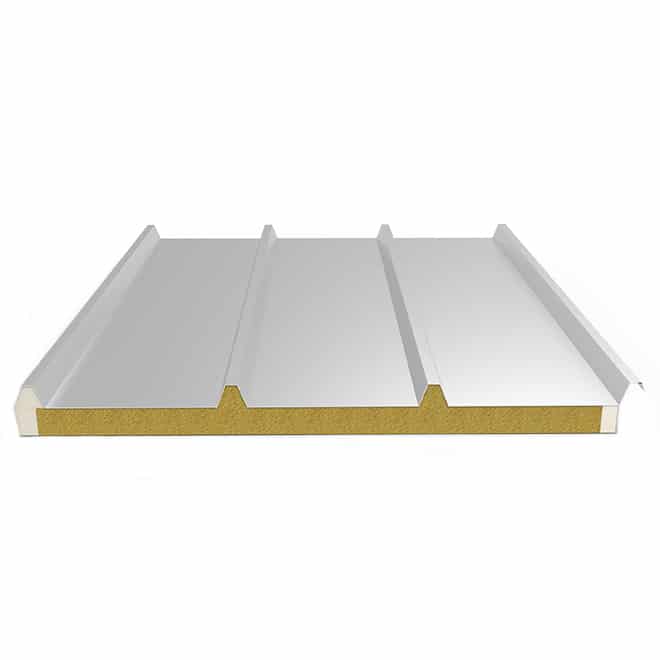

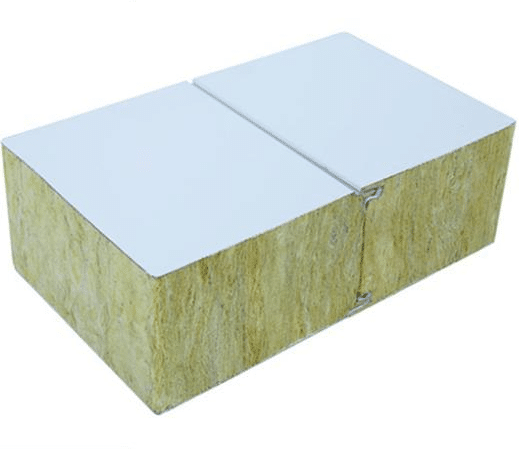

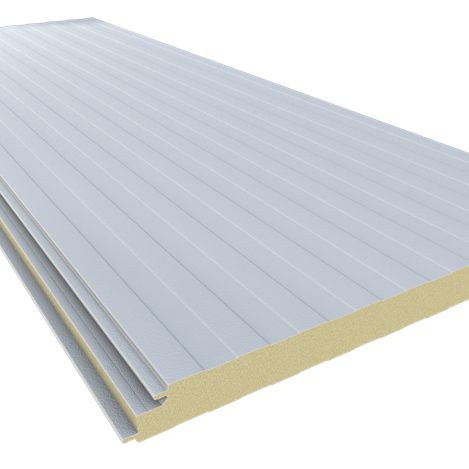

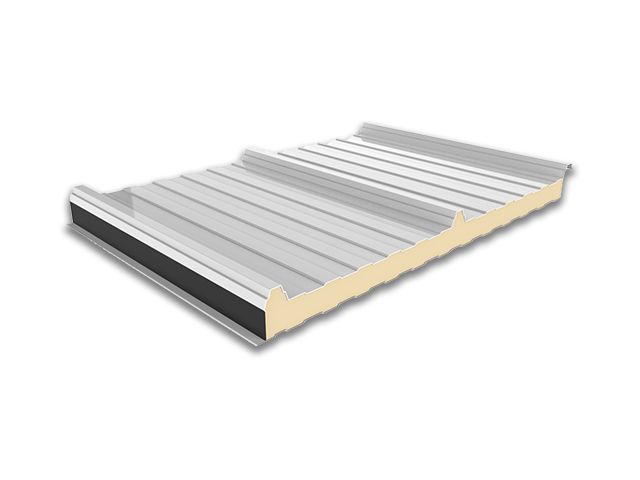

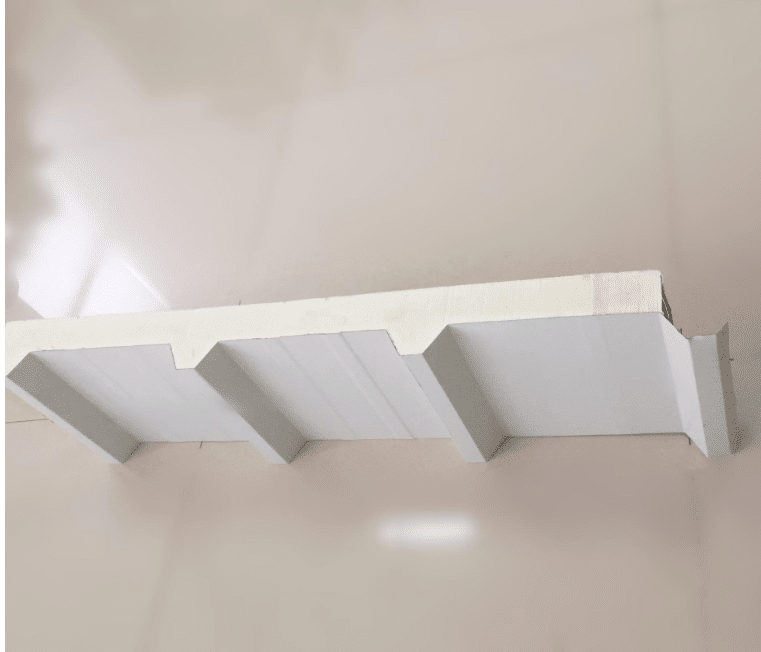

- Wall and Roof Insulation: Foam glass is widely used as an insulation material for building walls and roofs. It can be installed as an exterior wall insulation layer, helping to maintain a comfortable indoor temperature throughout the year and reducing energy consumption for heating and cooling. In addition, its fire – resistance and moisture – resistance properties make it a safe and durable choice for roof insulation, protecting the building structure from the elements.

- Fire – Resistant Barriers: Due to its A – class fire – resistant property, foam glass is an ideal material for constructing fire – resistant barriers within buildings. It can be used to separate different fire – zones, such as in stairwells, corridors, and between different functional areas of a building, providing an important line of defense against the spread of fire.

- Sound – Insulating Applications: In buildings where sound insulation is crucial, such as in recording studios, concert halls, and high – end residential apartments, foam glass can be incorporated into the interior design to reduce noise transmission between rooms or from external sources.

4.2 Industrial Applications

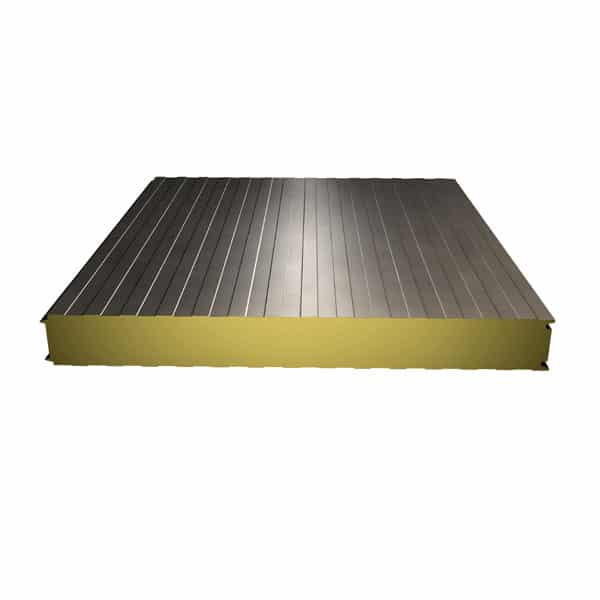

- Insulation of Pipes and Equipment: In industrial plants, foam glass is commonly used to insulate pipes that carry hot or cold fluids, as well as industrial equipment such as boilers, reactors, and storage tanks. Its excellent thermal insulation, chemical stability, and mechanical strength ensure that the temperature – sensitive processes are maintained efficiently and that the equipment operates safely and reliably in harsh industrial environments.

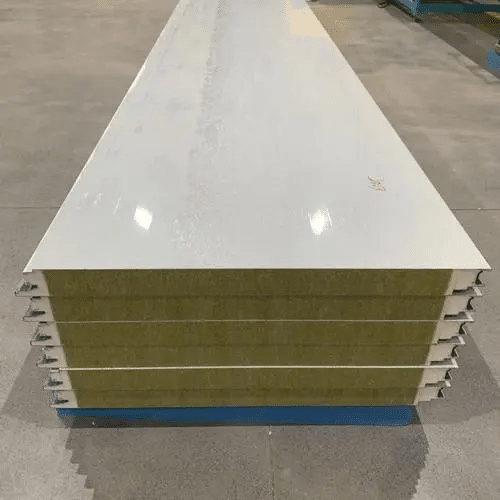

- Cold – Storage Facilities: Foam glass is highly suitable for use in cold – storage warehouses and refrigeration systems. Its low thermal conductivity and moisture resistance prevent heat from entering the cold – storage space, reducing the energy consumption of refrigeration equipment and ensuring the quality of stored products.

- Chemical Industry: Given its chemical resistance, foam glass is used in the chemical industry for applications where contact with corrosive chemicals is inevitable. It can be used as insulation for equipment and pipelines in chemical production processes, protecting the underlying structures from chemical corrosion and extending their service life.

4.3 Transportation and Marine Industry

- Shipbuilding: In shipbuilding, foam glass is used for insulation in ship cabins, engine rooms, and refrigerated cargo holds. Its lightweight nature helps to reduce the overall weight of the ship, improving fuel efficiency. At the same time, its fire – resistance, moisture – resistance, and sound – absorption properties contribute to a safer, more comfortable, and quieter onboard environment.

- Railway and Automotive Applications: In the railway and automotive industries, foam glass can be used for insulation and sound – proofing in train carriages and vehicle interiors. It helps to improve the thermal comfort of passengers and reduces noise levels, enhancing the overall travel experience.

5. Environmental Benefits

6. Conclusion

Detailed Shipping Options Introduction

At Wanxing, we offer flexible shipping options tailored to your procurement needs. Strategically located near Qingdao, a major port city renowned for its robust shipping infrastructure, we provide two convenient choices to suit your project demands:

- Our Full Shipping Service: Let us handle the logistics from start to finish. We’ll manage the entire process—from packing your EIFS panels at our facility near Qingdao to delivering them directly to your construction site. Leveraging Qingdao Port’s efficient sea and air transport networks, we can ship to key markets like Europe (e.g., Rotterdam in 20-30 days via sea), North America (e.g., Los Angeles in 25-35 days), or other global destinations. Our team coordinates with trusted freight forwarders to ensure timely delivery, keeping your project on schedule. This turnkey solution is ideal if you prefer a hands-off approach with guaranteed reliability.

- Self-Pickup with Ex-Factory Pricing: For maximum cost control, opt to collect your panels directly from our facility near Qingdao or at Qingdao Port. With ex-factory pricing, you avoid additional shipping markups and can arrange your own logistics—whether sea freight for bulk orders (e.g., containers of 500+ panels) or air freight for urgent needs. This option lets you optimize shipping costs and timelines based on your preferred carriers and routes, offering flexibility for tight budgets or specific delivery windows.

To support either choice, we provide all necessary documentation, including invoices, packing lists, and customs forms, ensuring compliance with international regulations. Need help with logistics? We can recommend experienced freight forwarders familiar with Qingdao’s export processes to streamline customs clearance and delivery to your site. Our goal is to make procurement seamless and cost-effective, whether you’re building in Europe, North America, or beyond. Want a shipping plan that perfectly fits your project’s budget and timeline? Contact us today to customize a solution from Qingdao, tailored to your needs.