Factory direct PU Edge Sealed Rock Wool Panels, custom sizes & colors available

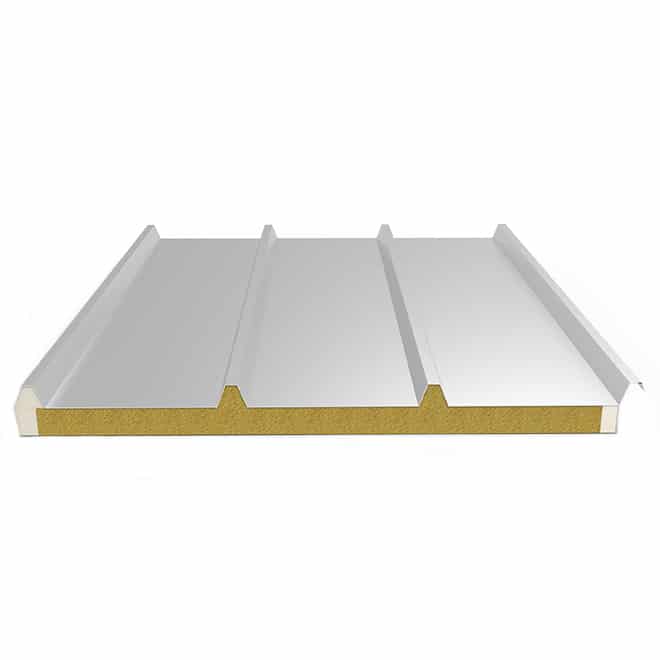

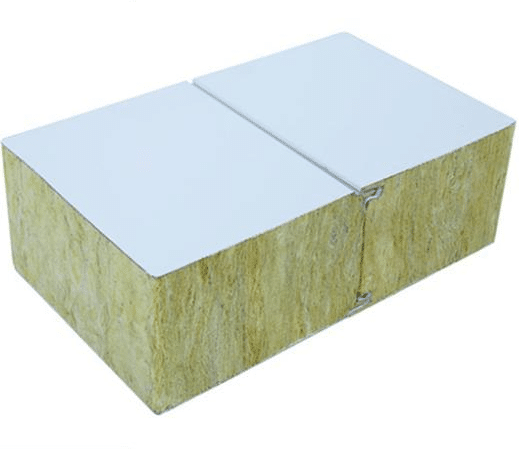

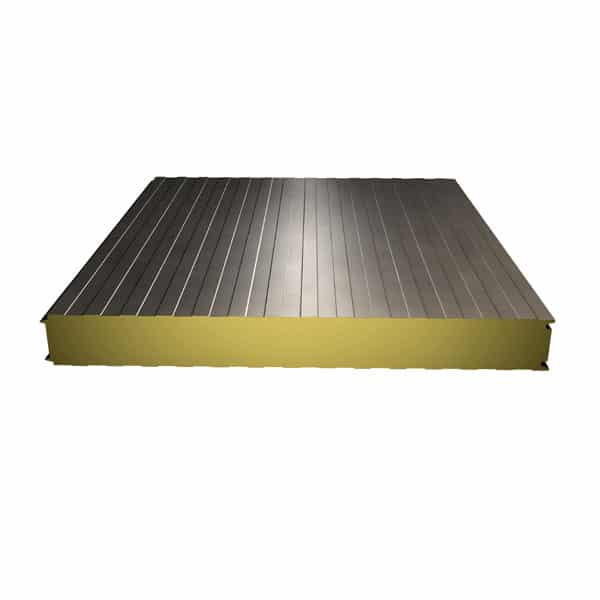

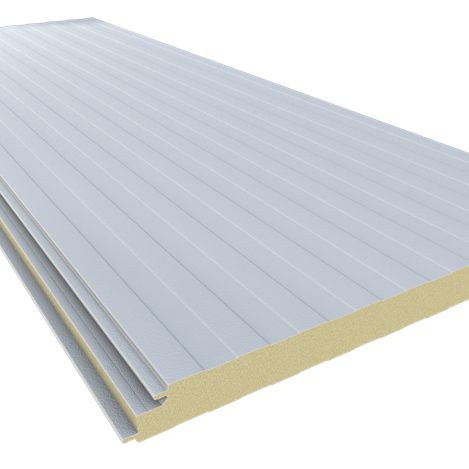

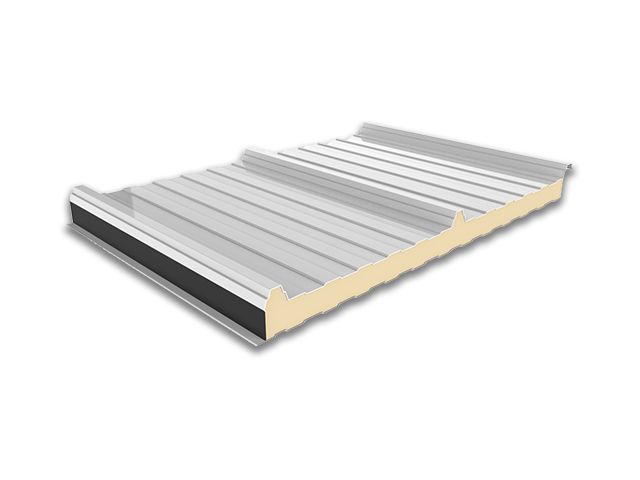

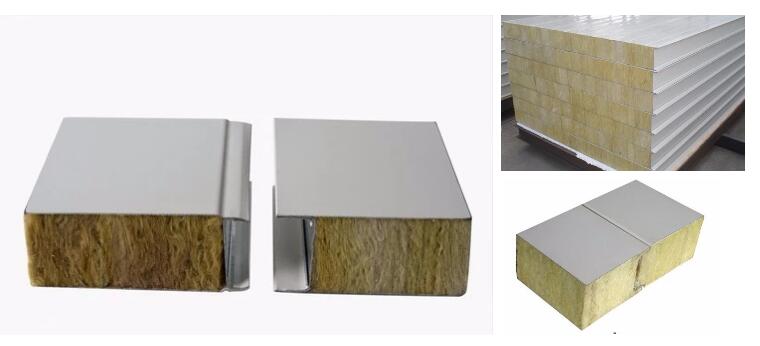

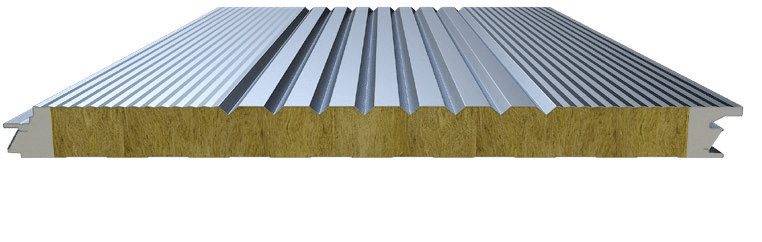

Polyurethane Edge Sealed Rock Wool Sandwich Panels are designed to provide exceptional fire resistance, thermal insulation, and long-term durability for industrial, commercial, and specialized construction projects. The A-Class fireproof rock wool core ensures maximum safety, while the polyurethane-sealed edges prevent moisture absorption, enhancing weather resistance and structural integrity.

Unlike many suppliers who outsource insulation materials and only handle basic panel assembly, we manufacture our own high-density rock wool and PU foam, ensuring superior quality control and cost efficiency for our customers. Our fully integrated production facility allows us to offer better performance, more stable supply, and competitive pricing.

🛠️ Technical Specifications

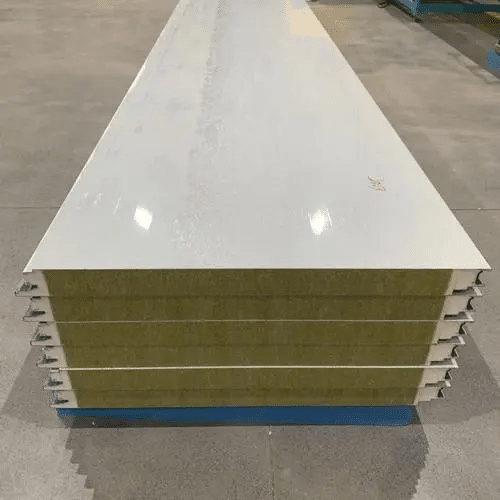

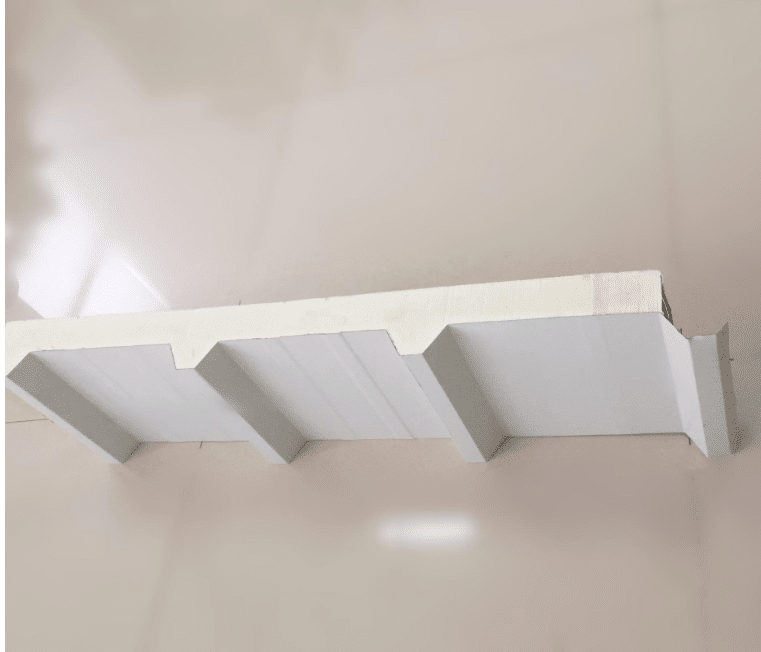

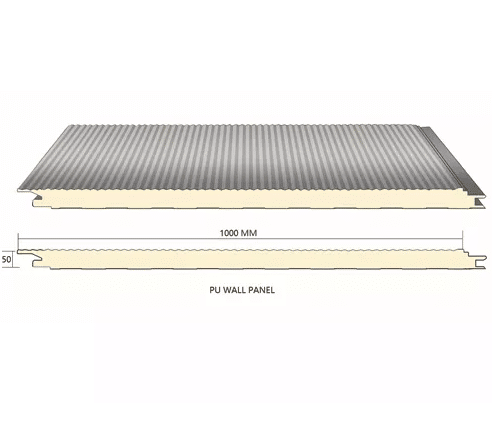

| Structure | Three layers: (1) Upper layer: steel sheet (2) Core layer: rock wool with PU-sealed edges (3) Bottom layer: steel sheet |

|---|---|

| Steel Thickness | 0.4–0.7mm |

| Panel Thickness | 50–200mm |

| Length | 1–11.8m |

| Effective Width | 1000mm |

| Core Material | High-density rock wool with polyurethane edge sealing |

| Rock Wool Density | 100–150 kg/m³ |

| PU Edge Sealing | Prevents moisture absorption and increases panel durability |

| Fire Resistance | A-Class (Non-combustible) |

| Thermal Conductivity | ≤ 0.04 W/(m·K) |

| Soundproofing | Reduces noise transmission effectively |

| Weather Resistance | UV-resistant, anti-corrosion, waterproof |

| Lifespan | About 30 years |

| Available Colors | RAL Color System |

| Packing | Shipped in containers or per customer requirements |

✅ Key Features & Advantages

🔥 A-Class Fire Resistance – Non-combustible rock wool core ensures the highest level of fire protection.

🛡 PU Edge Sealing Technology – Prevents water penetration, increasing panel lifespan and preventing insulation degradation.

❄️ Superior Thermal Insulation – Rock wool with polyurethane edges minimizes heat loss, reducing energy costs.

🔇 Excellent Soundproofing – High-density core significantly reduces noise transmission.

💪 High Load-Bearing Capacity – Strong steel construction withstands wind, snow, and impact forces.

🌦 Weather & Corrosion Resistance – Anti-corrosion coatings and UV protection ensure durability in harsh environments.

⚡ Lightweight & Easy Installation – Reduces structural load and shortens construction time.

💰 Cost Efficiency – In-house material production reduces costs, passing savings to customers.

🏗️ Applications

🏭 Industrial & Commercial Buildings – Factories, warehouses, logistics centers, showrooms.

❄️ Cold Storage & Refrigeration – Temperature-controlled warehouses, food storage, and pharmaceutical facilities.

🔬 Clean Rooms & Laboratories – Hygienic environments requiring fire-resistant and insulated walls.

🏢 Office & Modular Buildings – Prefabricated office spaces, modular homes, and steel structure constructions.

🎧 Soundproof Enclosures – Noise control walls for manufacturing plants, auditoriums, and airports.

📩 Request a Free Quote Today!

📌 Why Choose Us Over Other Suppliers?

🚀 In-House Material Production – Unlike most manufacturers, we produce our own rock wool and PU foam, ensuring better quality and lower costs.

🏭 Full Manufacturing Facility – We own a fully integrated factory, not just an assembly workshop, guaranteeing consistent supply & high production capacity.

🛠 Custom Solutions Available – We provide tailored panel thickness, steel coatings, and colors based on project requirements.

🌎 Proven Global Experience – Trusted by clients worldwide, with international certifications (CE, ISO, etc.) ensuring quality compliance.

💰 Competitive Pricing – By cutting out middlemen and producing our own insulation, we help customers save on material costs.

📩 Contact us now for detailed product specifications & best pricing! 🚀

Detailed Shipping Options Introduction

At Wanxing, we offer flexible shipping options tailored to your procurement needs. Strategically located near Qingdao, a major port city renowned for its robust shipping infrastructure, we provide two convenient choices to suit your project demands:

- Our Full Shipping Service: Let us handle the logistics from start to finish. We’ll manage the entire process—from packing your EIFS panels at our facility near Qingdao to delivering them directly to your construction site. Leveraging Qingdao Port’s efficient sea and air transport networks, we can ship to key markets like Europe (e.g., Rotterdam in 20-30 days via sea), North America (e.g., Los Angeles in 25-35 days), or other global destinations. Our team coordinates with trusted freight forwarders to ensure timely delivery, keeping your project on schedule. This turnkey solution is ideal if you prefer a hands-off approach with guaranteed reliability.

- Self-Pickup with Ex-Factory Pricing: For maximum cost control, opt to collect your panels directly from our facility near Qingdao or at Qingdao Port. With ex-factory pricing, you avoid additional shipping markups and can arrange your own logistics—whether sea freight for bulk orders (e.g., containers of 500+ panels) or air freight for urgent needs. This option lets you optimize shipping costs and timelines based on your preferred carriers and routes, offering flexibility for tight budgets or specific delivery windows.

To support either choice, we provide all necessary documentation, including invoices, packing lists, and customs forms, ensuring compliance with international regulations. Need help with logistics? We can recommend experienced freight forwarders familiar with Qingdao’s export processes to streamline customs clearance and delivery to your site. Our goal is to make procurement seamless and cost-effective, whether you’re building in Europe, North America, or beyond. Want a shipping plan that perfectly fits your project’s budget and timeline? Contact us today to customize a solution from Qingdao, tailored to your needs.