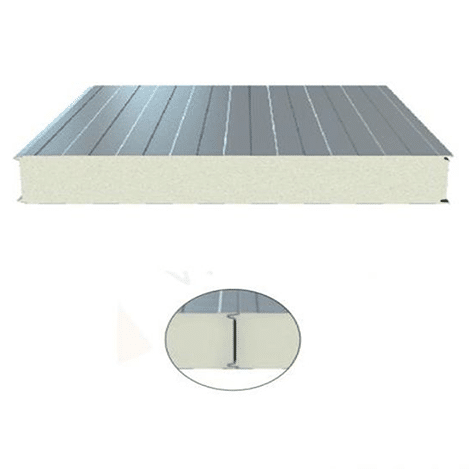

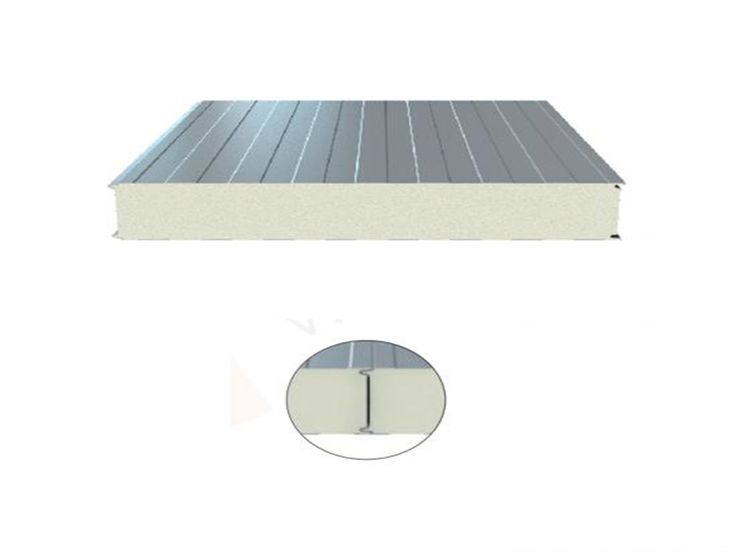

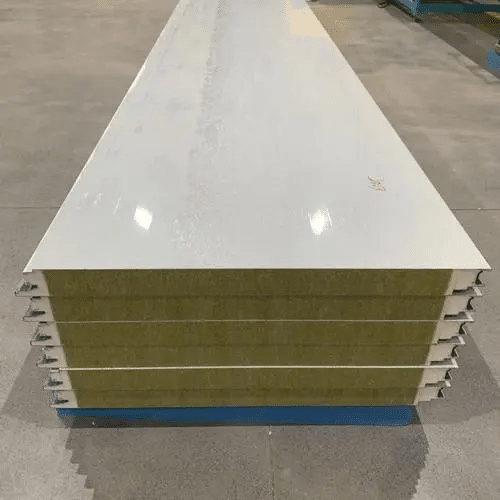

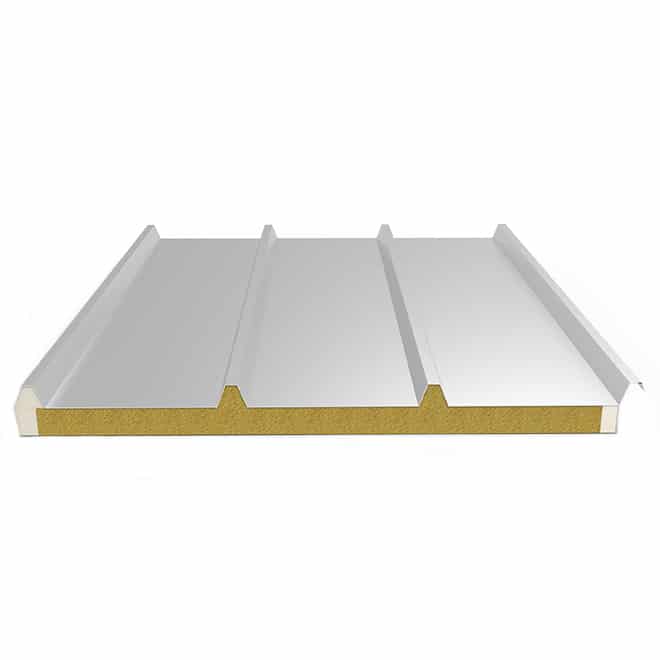

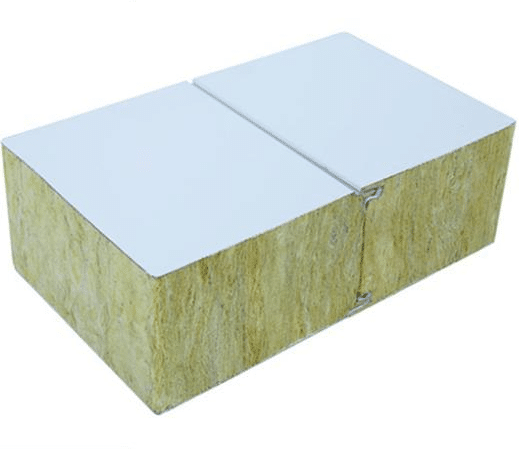

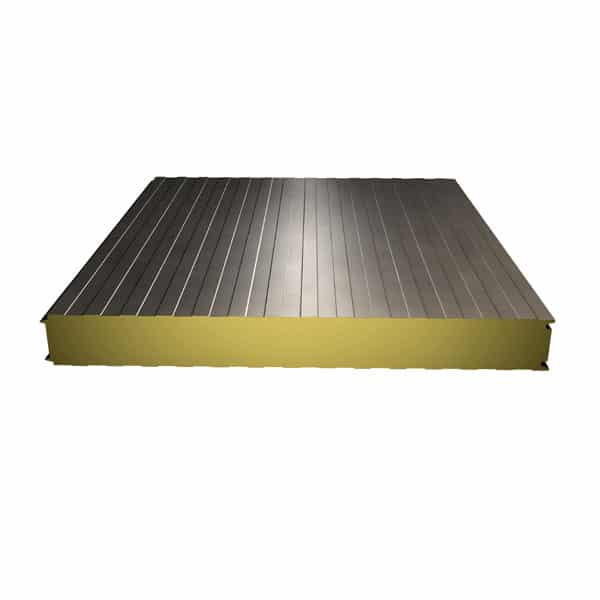

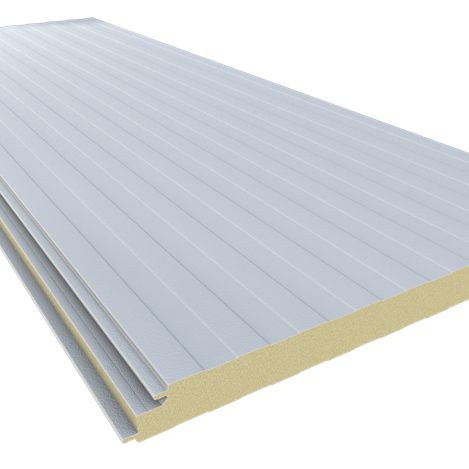

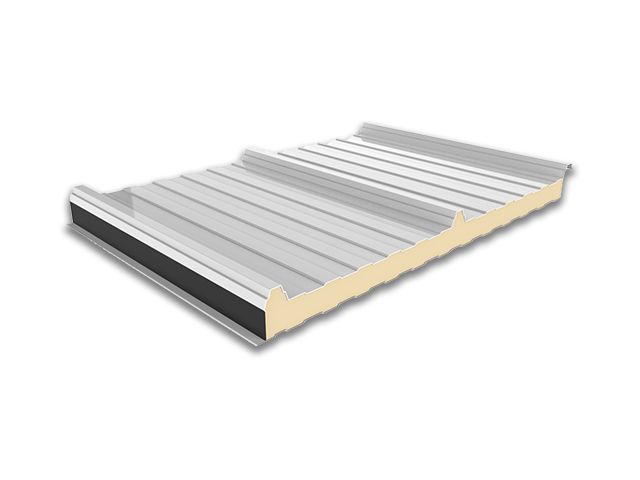

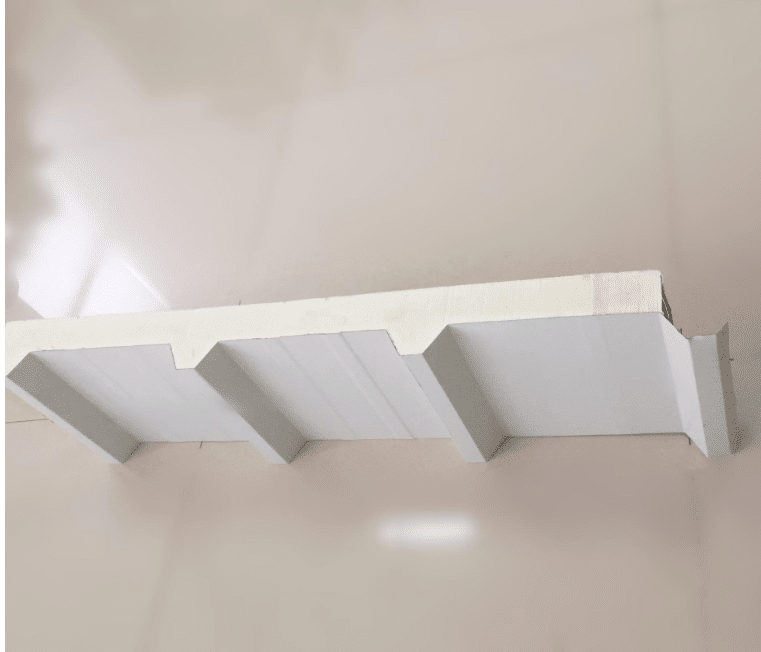

Rock Wool Composite Panel

Main Structure:

-

- Insulation Layer (Rock Wool): The core material is rock wool with vertically aligned fibers, providing excellent thermal insulation performance.

-

- Bonding Material (Cementitious Material, Inorganic): Used to firmly bond the rock wool with other layers, typically employing inorganic cementitious materials to enhance overall structural stability and durability.

-

- Surface Finish Layer: An outer decorative or protective coating that improves appearance and enhances waterproof and moisture-resistant properties.

Main Features:

-

- Waterproof, Moisture-Resistant, and Hydrophobic: The surface undergoes hydrophobic treatment, effectively preventing water penetration and adapting to humid environments.

-

- Thermal Insulation: The high thermal resistance of rock wool significantly reduces heat conduction, delivering outstanding energy-saving effects.

-

- A1 Fire Rating: Meets the highest fireproof standard, completely non-combustible, ensuring safety.

-

- Uniform Thickness: The manufacturing process ensures consistent board thickness, facilitating easy installation and use.

-

- Sound Insulation and Noise Reduction: The fibrous structure of rock wool effectively absorbs sound waves, reducing noise interference.

Application Scope:

-

- Cold Storage Projects: Due to its insulation and waterproof properties, it is commonly used in walls and roofs of cold chain facilities.

-

- Large Warehouses: Provides fire protection and thermal insulation, ensuring storage safety.

-

- Chemical Plants: Its corrosion resistance and fireproof characteristics make it suitable for the special environments of the chemical industry.

- Additionally, it can be applied in other industrial or civil buildings requiring high-performance insulation and fire resistance.

Detailed Shipping Options Introduction

At Wanxing, we offer flexible shipping options tailored to your procurement needs. Strategically located near Qingdao, a major port city renowned for its robust shipping infrastructure, we provide two convenient choices to suit your project demands:

- Our Full Shipping Service: Let us handle the logistics from start to finish. We’ll manage the entire process—from packing your EIFS panels at our facility near Qingdao to delivering them directly to your construction site. Leveraging Qingdao Port’s efficient sea and air transport networks, we can ship to key markets like Europe (e.g., Rotterdam in 20-30 days via sea), North America (e.g., Los Angeles in 25-35 days), or other global destinations. Our team coordinates with trusted freight forwarders to ensure timely delivery, keeping your project on schedule. This turnkey solution is ideal if you prefer a hands-off approach with guaranteed reliability.

- Self-Pickup with Ex-Factory Pricing: For maximum cost control, opt to collect your panels directly from our facility near Qingdao or at Qingdao Port. With ex-factory pricing, you avoid additional shipping markups and can arrange your own logistics—whether sea freight for bulk orders (e.g., containers of 500+ panels) or air freight for urgent needs. This option lets you optimize shipping costs and timelines based on your preferred carriers and routes, offering flexibility for tight budgets or specific delivery windows.

To support either choice, we provide all necessary documentation, including invoices, packing lists, and customs forms, ensuring compliance with international regulations. Need help with logistics? We can recommend experienced freight forwarders familiar with Qingdao’s export processes to streamline customs clearance and delivery to your site. Our goal is to make procurement seamless and cost-effective, whether you’re building in Europe, North America, or beyond. Want a shipping plan that perfectly fits your project’s budget and timeline? Contact us today to customize a solution from Qingdao, tailored to your needs.