Cold Room Panels | Panel Manufacturers

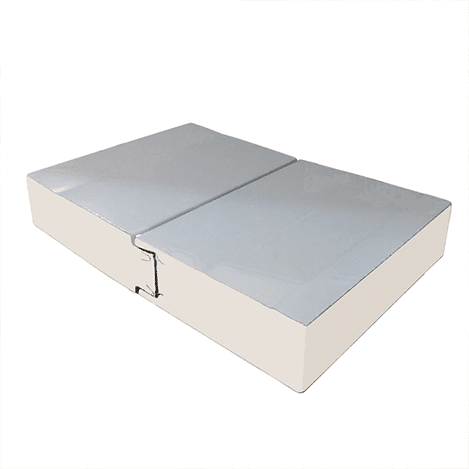

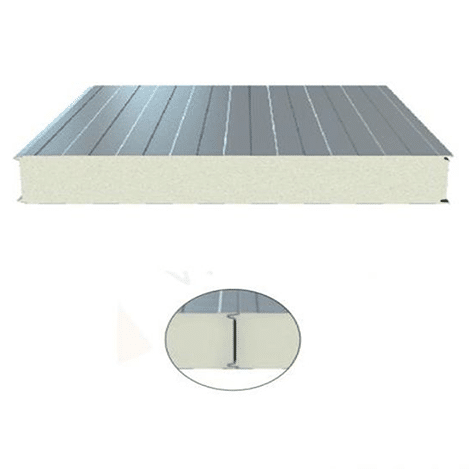

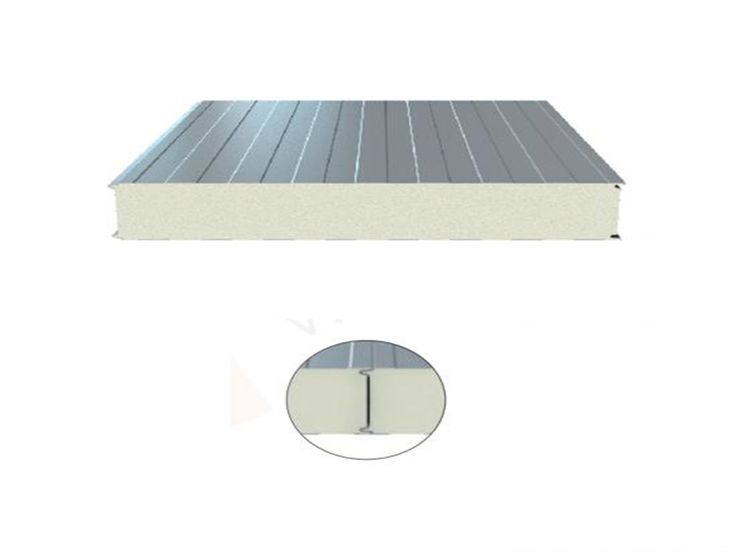

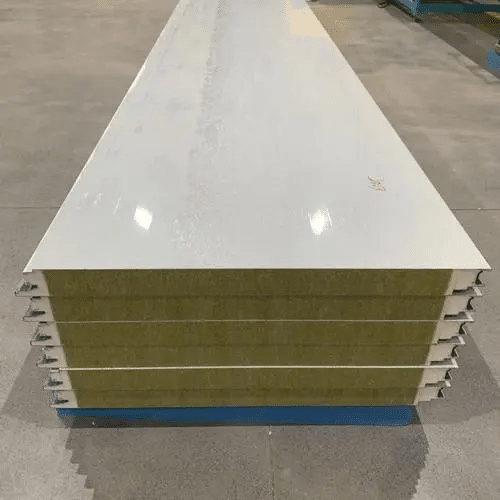

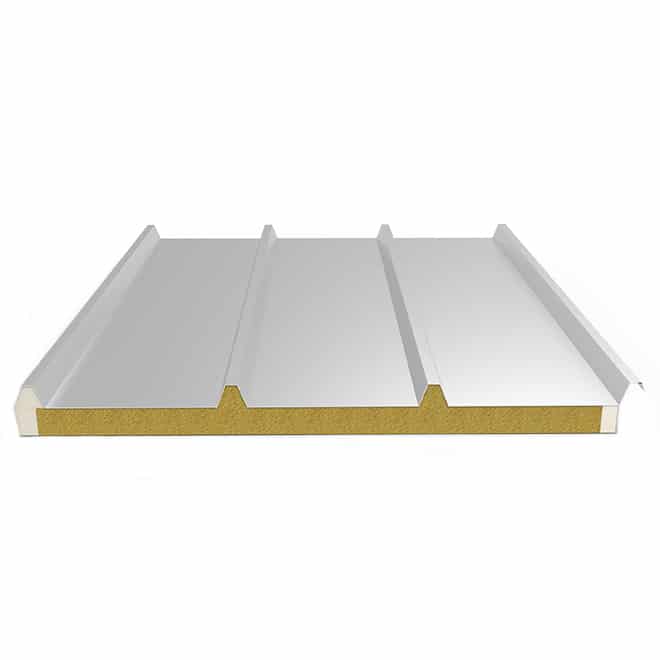

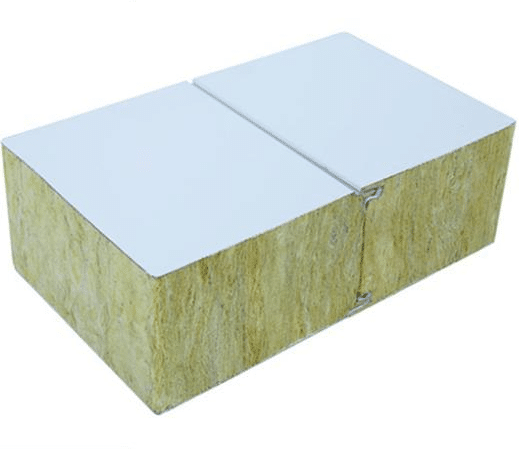

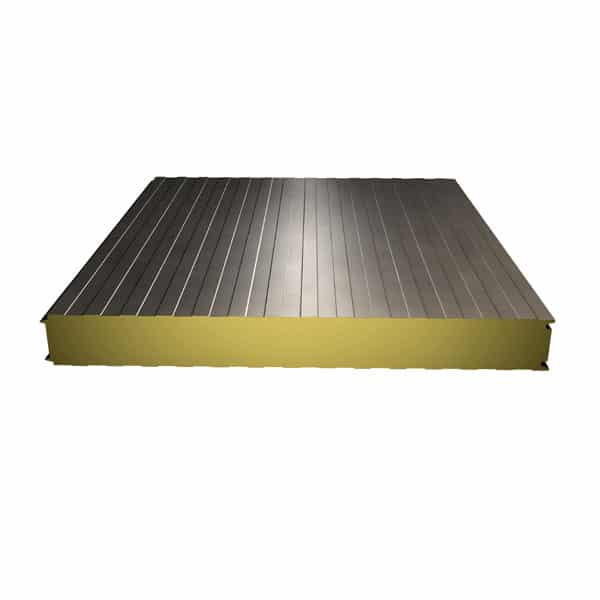

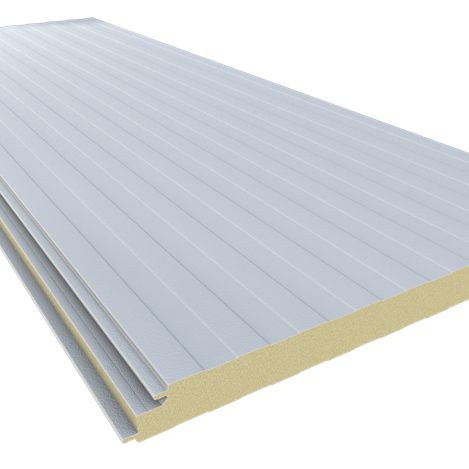

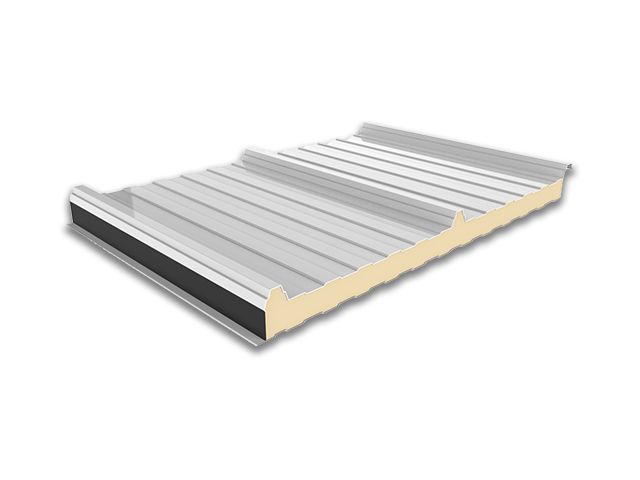

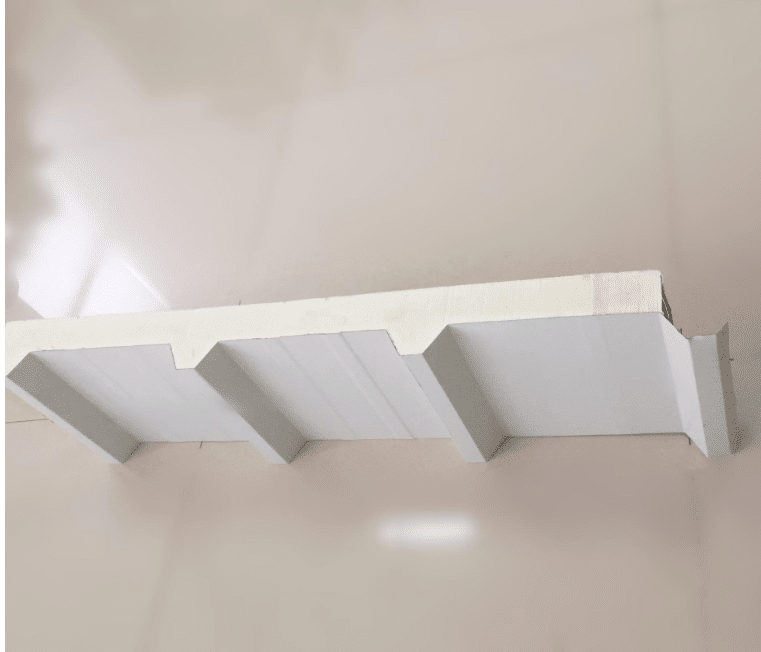

Cold room panels are an essential component in the construction of temperature-controlled environments, offering reliable insulation and structural performance. Engineered with a high-density polyurethane (PU) core and finished with protective metal facings, these panels help maintain consistent internal temperatures while withstanding demanding operating conditions.

Product Highlights

-

Customizable Thickness Options: Available in a range of thicknesses—50mm to 200mm—designed to match diverse cold storage requirements from chillers to deep-freeze rooms.

-

Low Thermal Conductivity: With insulation values reaching as low as 0.022 W/m·K, cold room panels contribute to reduced energy consumption and efficient refrigeration.

-

Noise Control Performance: Sound insulation rated up to 30dB makes these panels suitable for applications where noise reduction is important.

-

Fire-Resistant Core: Panels are manufactured using fire-rated materials, supporting compliance with safety standards for industrial and commercial environments.

-

Variable Panel Sizes: Effective width options from 500mm to 1150mm and lengths up to 12 meters ensure flexibility across different project scales.

-

Surface Material Options:

-

Polyester-coated galvanized steel (25µm)

-

High-zinc layers (Zn 50 – Zn 180g/m²)

-

Stainless steel for enhanced corrosion protection

-

Common Use Scenarios

-

Refrigerated warehouses and logistics centers

-

Food processing and pharmaceutical production rooms

-

Modular cold rooms and commercial freezer facilities

-

Controlled-temperature enclosures for industrial applications

Built for thermal efficiency and structural strength, our cold room panels are trusted by contractors and system integrators worldwide to ensure reliable performance in climate-sensitive environments.

Detailed Shipping Options Introduction

At Wanxing, we offer flexible shipping options tailored to your procurement needs. Strategically located near Qingdao, a major port city renowned for its robust shipping infrastructure, we provide two convenient choices to suit your project demands:

- Our Full Shipping Service: Let us handle the logistics from start to finish. We’ll manage the entire process—from packing your EIFS panels at our facility near Qingdao to delivering them directly to your construction site. Leveraging Qingdao Port’s efficient sea and air transport networks, we can ship to key markets like Europe (e.g., Rotterdam in 20-30 days via sea), North America (e.g., Los Angeles in 25-35 days), or other global destinations. Our team coordinates with trusted freight forwarders to ensure timely delivery, keeping your project on schedule. This turnkey solution is ideal if you prefer a hands-off approach with guaranteed reliability.

- Self-Pickup with Ex-Factory Pricing: For maximum cost control, opt to collect your panels directly from our facility near Qingdao or at Qingdao Port. With ex-factory pricing, you avoid additional shipping markups and can arrange your own logistics—whether sea freight for bulk orders (e.g., containers of 500+ panels) or air freight for urgent needs. This option lets you optimize shipping costs and timelines based on your preferred carriers and routes, offering flexibility for tight budgets or specific delivery windows.

To support either choice, we provide all necessary documentation, including invoices, packing lists, and customs forms, ensuring compliance with international regulations. Need help with logistics? We can recommend experienced freight forwarders familiar with Qingdao’s export processes to streamline customs clearance and delivery to your site. Our goal is to make procurement seamless and cost-effective, whether you’re building in Europe, North America, or beyond. Want a shipping plan that perfectly fits your project’s budget and timeline? Contact us today to customize a solution from Qingdao, tailored to your needs.