Aluminum Composite Panel (ACP)

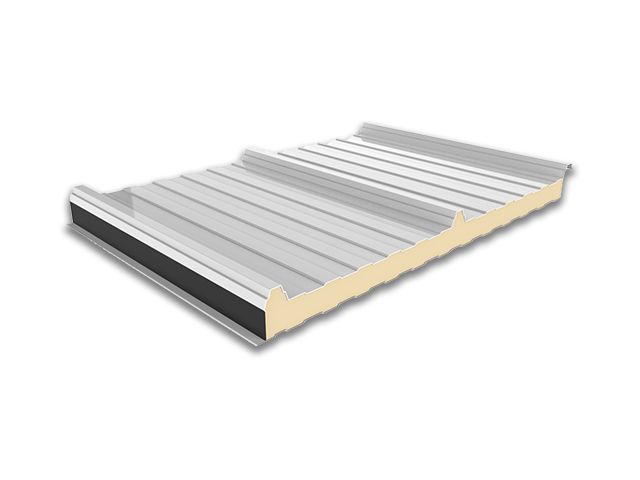

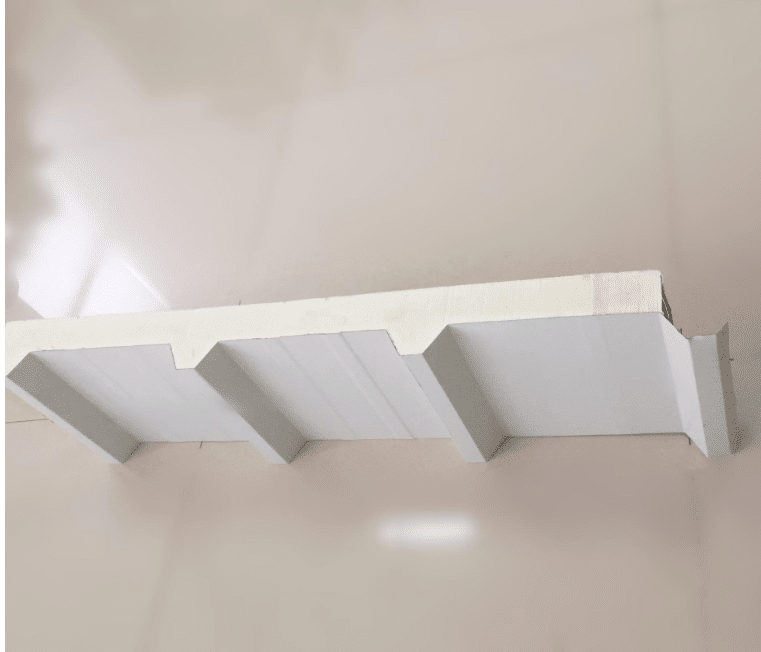

Aluminum Composite Panel (ACP) is a high-performance building material composed of two aluminum sheets, typically 0.1 mm to 0.5 mm thick, bonded to a solid core using advanced adhesive technology. The core material varies depending on the intended use: standard ACP uses polyethylene (PE) for general purposes, while fire-resistant versions use mineral-filled cores like magnesium hydroxide or aluminum hydroxide. The surface of the aluminum is often coated with protective layers such as PVDF (polyvinylidene fluoride) or polyester for enhanced durability and weather resistance. ACP panels are manufactured in thicknesses ranging from 2 mm to 6 mm, with common sizes like 1220 mm x 2440 mm.

Key characteristics include:

-

- Lightweight: Weighing about 5.5–7.5 kg/m², it reduces structural load.

-

- High Strength: The composite structure offers excellent rigidity and impact resistance.

-

- Weather Resistance: PVDF coatings withstand UV rays, corrosion, and extreme temperatures (-50°C to 80°C).

-

- Fire Performance: Fire-rated ACP (e.g., B1 or A2 grade) limits flame spread and smoke production.

-

- Sound Insulation: The core dampens sound, providing moderate acoustic benefits.

-

- Ease of Fabrication: Can be cut, bent, or shaped with standard tools for complex designs.

ACP is widely used in:

-

- Exterior Cladding: Curtain walls and building facades for modern skyscrapers.

-

- Interior Decoration: Wall panels, ceilings, and partitions in offices or homes.

-

- Signage: Billboards and shopfront displays due to its smooth finish and color variety.

- Industrial Use: Protective covers or insulation in factories.

Detailed Shipping Options Introduction

At Wanxing, we offer flexible shipping options tailored to your procurement needs. Strategically located near Qingdao, a major port city renowned for its robust shipping infrastructure, we provide two convenient choices to suit your project demands:

- Our Full Shipping Service: Let us handle the logistics from start to finish. We’ll manage the entire process—from packing your EIFS panels at our facility near Qingdao to delivering them directly to your construction site. Leveraging Qingdao Port’s efficient sea and air transport networks, we can ship to key markets like Europe (e.g., Rotterdam in 20-30 days via sea), North America (e.g., Los Angeles in 25-35 days), or other global destinations. Our team coordinates with trusted freight forwarders to ensure timely delivery, keeping your project on schedule. This turnkey solution is ideal if you prefer a hands-off approach with guaranteed reliability.

- Self-Pickup with Ex-Factory Pricing: For maximum cost control, opt to collect your panels directly from our facility near Qingdao or at Qingdao Port. With ex-factory pricing, you avoid additional shipping markups and can arrange your own logistics—whether sea freight for bulk orders (e.g., containers of 500+ panels) or air freight for urgent needs. This option lets you optimize shipping costs and timelines based on your preferred carriers and routes, offering flexibility for tight budgets or specific delivery windows.

To support either choice, we provide all necessary documentation, including invoices, packing lists, and customs forms, ensuring compliance with international regulations. Need help with logistics? We can recommend experienced freight forwarders familiar with Qingdao’s export processes to streamline customs clearance and delivery to your site. Our goal is to make procurement seamless and cost-effective, whether you’re building in Europe, North America, or beyond. Want a shipping plan that perfectly fits your project’s budget and timeline? Contact us today to customize a solution from Qingdao, tailored to your needs.