Blog

What Are PU and PIR Sandwich Panels and What Are They Used For?

PU (Polyurethane) and PIR (Polyisocyanurate) sandwich panels are high-efficiency thermal insulation materials used in modern construction. Designed for wall and roof applications, these panels offer excellent energy-saving performance, structural durability, and fire resistance. Widely used in cold storage, industrial buildings, logistics centers, and prefabricated projects, PU and PIR panels are a top choice for international buyers seeking reliable and cost-effective solutions.

What Are PU and PIR Sandwich Panels?

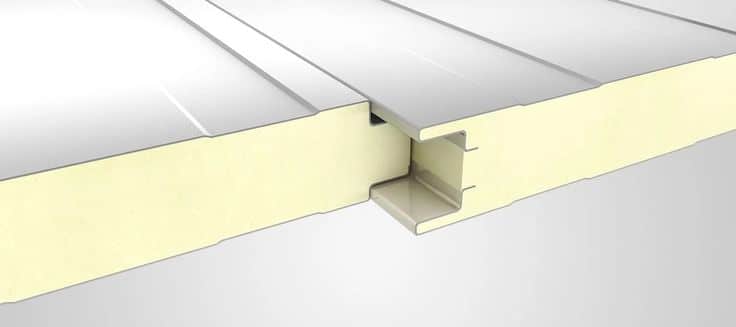

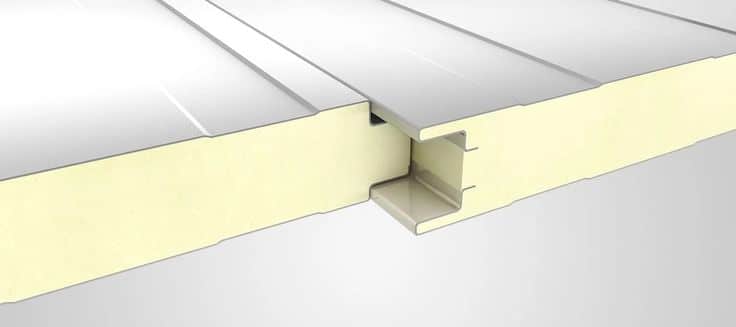

Sandwich panels are prefabricated construction materials composed of two outer metal sheets and a rigid foam core. The core material — either PU or PIR — provides thermal insulation and contributes to the panel’s strength and stability.

- PU (Polyurethane) panels are known for their excellent insulation and cost efficiency.

- PIR (Polyisocyanurate) panels offer even better fire performance while maintaining low thermal conductivity.

Both types are widely exported and meet the technical standards required in various countries across industrial, commercial, and cold chain sectors.

Advantages of PU and PIR Sandwich Panels

🔹 Superior Thermal Insulation

PU and PIR cores provide low thermal conductivity, minimizing energy loss in buildings. This is especially critical in regions with extreme climates — hot or cold.

🔹 Fire Resistance (PIR Panels)

PIR panels offer enhanced fire resistance compared to traditional PU, making them suitable for buildings with strict fire safety codes. They maintain structure integrity longer under high temperatures.

🔹 Lightweight and Easy Installation

Sandwich panels are lightweight yet strong, allowing for quick transportation and fast on-site installation. They reduce construction time and labor costs significantly.

🔹 Customizable Sizes

Standard width is 1000mm or 1150mm, with lengths up to 16 meters. Thickness can range from 40mm to 200mm, depending on application. Customization is available based on project requirements.

🔹 Versatile Surface Finishes

Surface options include pre-painted galvanized steel (PPGI), stainless steel, and aluminum sheets. Different finishes are available for both aesthetic and functional purposes.

Applications of PU and PIR Sandwich Panels

These panels are suitable for a wide range of applications in global markets:

✅ Industrial Buildings

Used as roofing and wall cladding for factories, warehouses, and logistics hubs, offering insulation, protection, and clean appearance.

✅ Cold Storage Facilities

Ideal for freezers and refrigeration units, PIR panels with thicker cores ensure high insulation and energy efficiency.

✅ Prefabricated Modular Buildings

Widely used in remote construction, temporary housing, and fast-deploy sites. Their lightweight structure and fast installation make them perfect for prefab applications.

✅ Clean Rooms and Food Processing Units

The anti-bacterial, easy-to-clean surface of sandwich panels makes them suitable for clean environments such as food factories, laboratories, and medical facilities.

Why Choose PU and PIR Panels for Your Project?

| Feature | PU Panel | PIR Panel |

|---|---|---|

| Thermal Insulation | ★★★★☆ | ★★★★☆ |

| Fire Resistance | ★★☆☆☆ | ★★★★★ |

| Cost | ★★★★☆ | ★★★☆☆ |

| Application | General insulation | Fire-sensitive areas |

For export buyers, both options provide reliable performance. PIR panels are ideal where fire rating is critical, while PU panels offer an economical choice for temperature-controlled buildings.

Export-Ready and Compliant

Our PU and PIR sandwich panels are manufactured under strict quality control, complying with international standards such as:

- ISO 9001: Quality Management

- CE Certification

- Fire and Thermal Insulation Ratings per buyer country

We offer custom packaging, container optimization, and full export documentation, ensuring smooth global delivery.

Get in Touch

Looking for a trusted supplier of PU and PIR sandwich panels from China?

We export to over 30 countries and provide tailored solutions for your project.

Contact us now to get technical specifications, pricing, and free samples.