Certified & Reliable

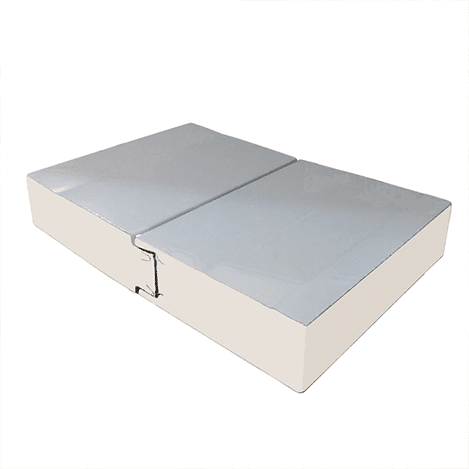

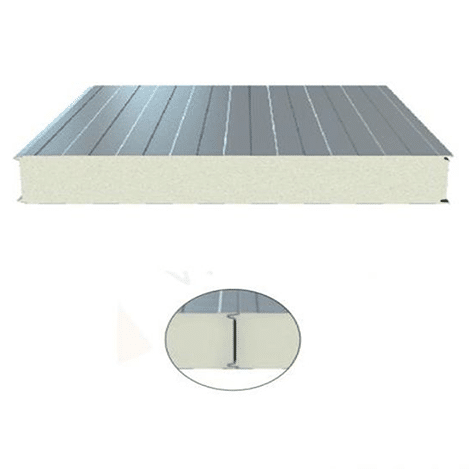

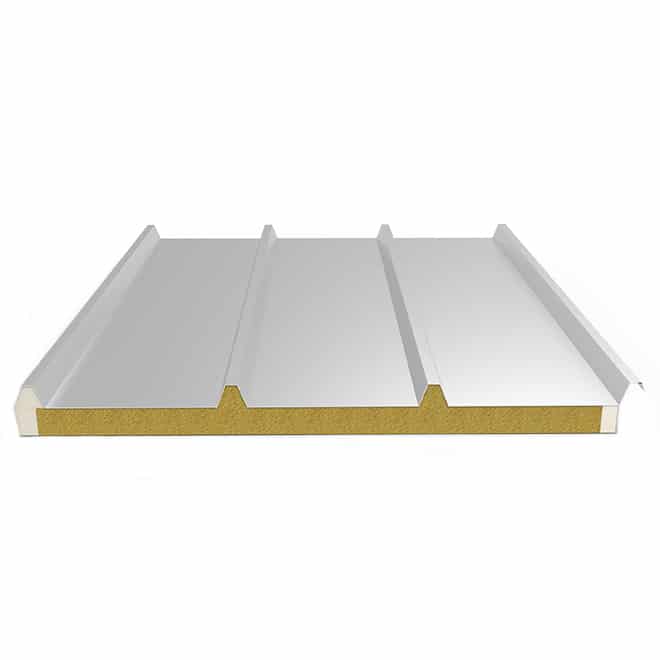

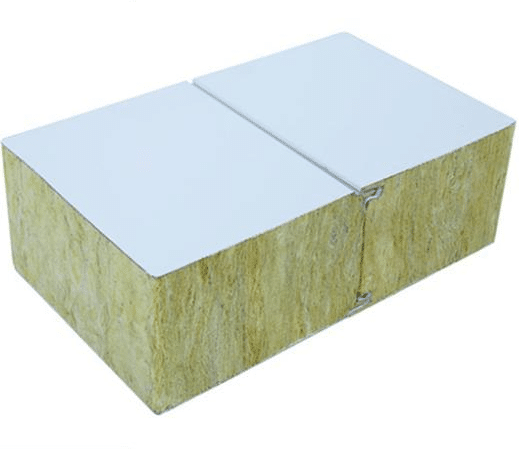

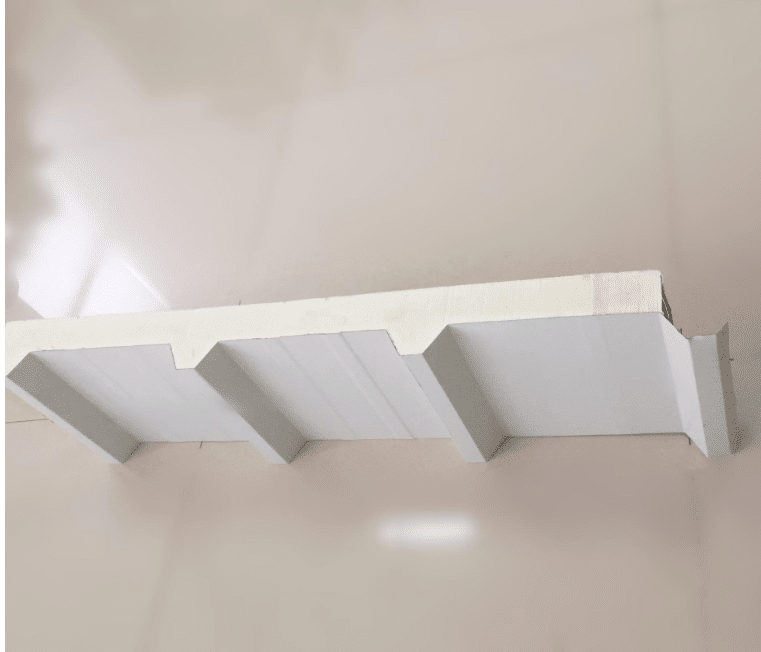

High-Performance Wall Insulation

— Our Products —

"Quality construction, eco-friendly products, trusted choice."

— Construction Case Study —

"Introduction of some of the projects undertaken"

“Based on advanced technology and quality service, we promote the energy-saving and environmental protection industry, contributing to the development of green buildings.”

Our New Articles

You can read our latest article that has solved the problems you are facing

25

Apr

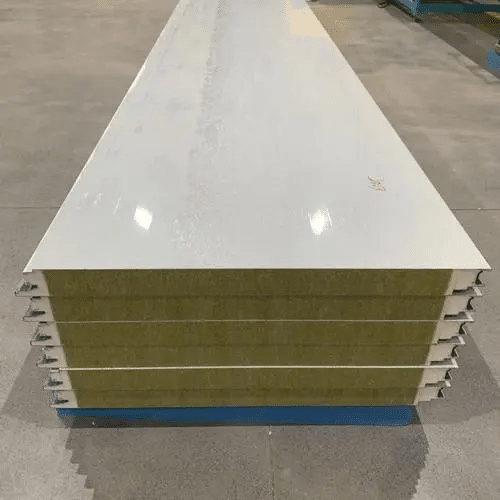

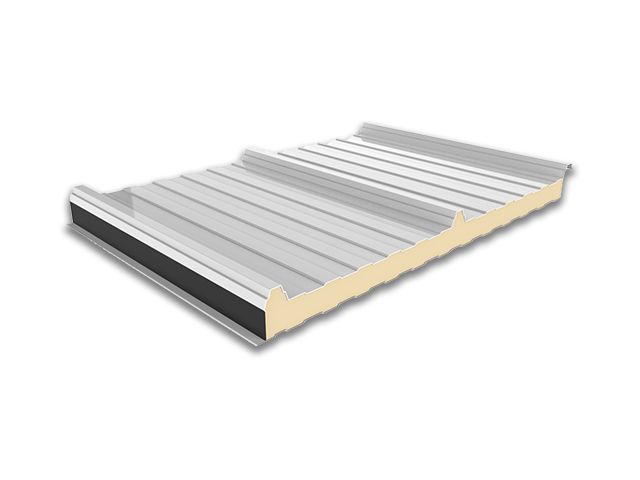

Sandwich Panels Manufacturing for Russia

As industrial and commercial construction standard...

23

Apr

Sandwich Panels Manufacturing for Saudi Arabia

At Wanxing-CHINA, we specialize in the manufacturi...

14

Apr

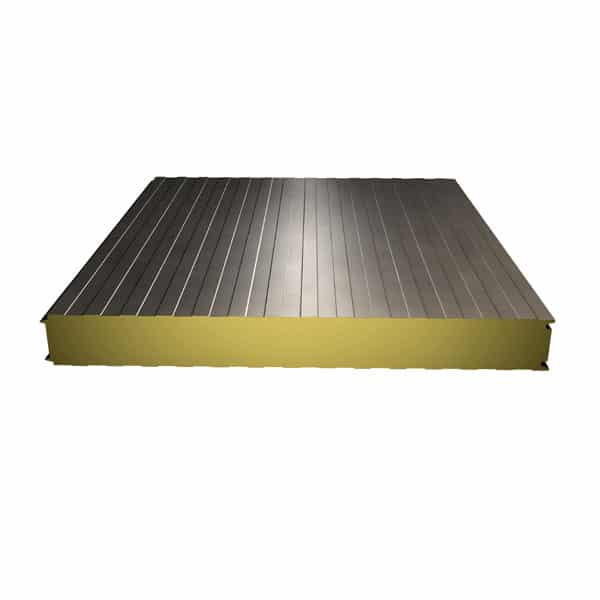

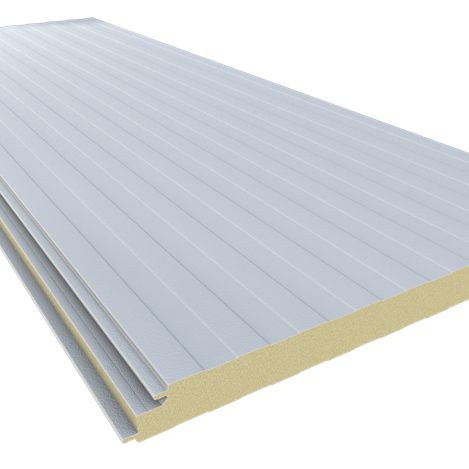

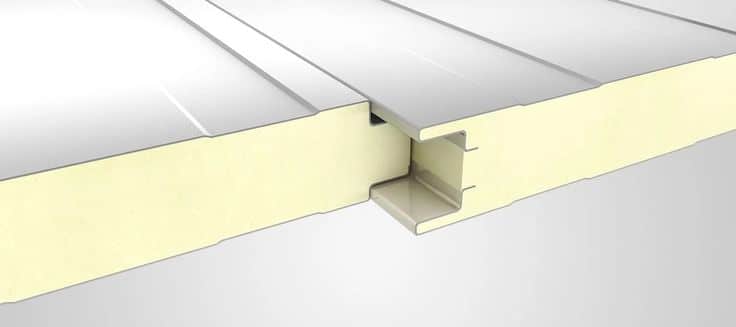

What Are PU and PIR Sandwich Panels and What Are They Used For?

PU (Polyurethane) and PIR (Polyisocyanurate) sandw...

06

Apr

China’s Crackdown on Invoice Buying: Price Hikes and a New Global Trade Landscape

In April 2025, China’s customs authorities introdu...

Get the latest base price for free

Sales Hotline

You can contact us below

- [email protected]

- +86 17852977913

- Jiangshan Town, Laixi District, Qingdao City, Shandong Province, China